cnc processed parts Quick Overview: – Key Benefits: Precision, repeatability, and material versatility. – Primary Industries: Aerospace, automotive, medical, consumer electronics. – Primary Materials: Aluminum, steel, titanium, plastics. Why CNC Machined Parts Matter. The big green electrical box, also known as an electrical service panel or breaker box, is a crucial component of your home’s electrical system. It regulates the flow of electricity, protects against electrical hazards, and requires regular maintenance to ensure optimal performance and safety.

0 · online cnc shop

1 · online cnc machine shop

2 · local cnc machine shops

3 · cnc machining parts usa

4 · cnc machining parts manufacturer

5 · cnc machining custom made parts

6 · cnc machine parts suppliers

7 · cnc machine parts online

Sheet metal screws are a special kind of fasteners that have been designed to join metal sheets or other thin materials together without the need for pre-drilling any holes. Such components are made with high precision as the sharp threads range from the tip and head thus direct insertion and fastening without any added components is possible.What are sheet metal screws? Sheet metal screws are specialized fasteners designed for securing metal sheets together or to other materials such as wood, plastic, or fiberglass.

However, what exactly defines CNC machine parts? And what attributes render them so vital? This article delves into CNC machining and CNC machined parts, compiling comprehensive and up-to-date information on all aspects you .

However, what exactly defines CNC machine parts? And what attributes render them so vital? This article delves into CNC machining and CNC machined parts, compiling comprehensive and up-to-date information on all aspects you should know.

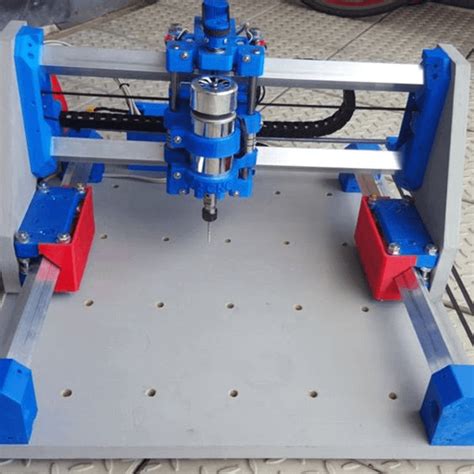

The CNC Machining Process: From CAD to Parts. The overall CNC machining process consists of four main steps, as listed below: 1. Designing the CAD Model. A CAD (Computer Aided Design) 3D model is developed by an engineer or designer. CNC, or Computer Numerical Control, encompasses the manufacturing process where machines cut, carve and form parts based on computer codes that control the cutting tool’s speed and movement. These machines cut metals, wood, foam, composites, plastics and more into precise parts with uses in almost every industry.Quick Overview: – Key Benefits: Precision, repeatability, and material versatility. – Primary Industries: Aerospace, automotive, medical, consumer electronics. – Primary Materials: Aluminum, steel, titanium, plastics. Why CNC Machined Parts Matter.CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools, shaping a variety of materials into custom parts and designs. There are several types of CNC machines, each with specific capabilities and applications.

online cnc shop

For gearbox, mining arm, car body, engine and other parts, small and medium-sized CNC machine tools are needed: CNC lathe, medium-sized machining center, CNC milling machine and gear processing machine tools.

Common parts manufactured using CNC turning include shafts, pins, bushings, and connectors. Its capability to efficiently machine rotational features, such as threads, grooves, and tapers, makes it ideal for a wide range of applications across industries. CNC machining is a subtractive manufacturing process in which a computer program guides different tools to create a product.

CNC Machined parts are components that are crafted using the CNC machining process. But what exactly is CNC machining? CNC Machining involves the use of subtractive cutting machines such as mills, lathes, and grinders to create a desired part.6 Effective Methods for Creating Aluminum Prototyping. CNC Machining Aluminum: Comprehensive Guide. The Ultimate Guide to Machining Teflon. Introduction: The Versatility of CNC Machining. CNC machining stands as a cornerstone in modern manufacturing. Its ability to shape a vast array of materials into precise parts makes it indispensable.

online cnc machine shop

However, what exactly defines CNC machine parts? And what attributes render them so vital? This article delves into CNC machining and CNC machined parts, compiling comprehensive and up-to-date information on all aspects you should know.

The CNC Machining Process: From CAD to Parts. The overall CNC machining process consists of four main steps, as listed below: 1. Designing the CAD Model. A CAD (Computer Aided Design) 3D model is developed by an engineer or designer. CNC, or Computer Numerical Control, encompasses the manufacturing process where machines cut, carve and form parts based on computer codes that control the cutting tool’s speed and movement. These machines cut metals, wood, foam, composites, plastics and more into precise parts with uses in almost every industry.Quick Overview: – Key Benefits: Precision, repeatability, and material versatility. – Primary Industries: Aerospace, automotive, medical, consumer electronics. – Primary Materials: Aluminum, steel, titanium, plastics. Why CNC Machined Parts Matter.CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools, shaping a variety of materials into custom parts and designs. There are several types of CNC machines, each with specific capabilities and applications.

local cnc machine shops

For gearbox, mining arm, car body, engine and other parts, small and medium-sized CNC machine tools are needed: CNC lathe, medium-sized machining center, CNC milling machine and gear processing machine tools. Common parts manufactured using CNC turning include shafts, pins, bushings, and connectors. Its capability to efficiently machine rotational features, such as threads, grooves, and tapers, makes it ideal for a wide range of applications across industries.

CNC machining is a subtractive manufacturing process in which a computer program guides different tools to create a product.CNC Machined parts are components that are crafted using the CNC machining process. But what exactly is CNC machining? CNC Machining involves the use of subtractive cutting machines such as mills, lathes, and grinders to create a desired part.

cnc machining parts usa

cnc machining parts manufacturer

cnc machining custom made parts

Custom Size, Finish, and Thickness for L Angle Timber Brackets You can select quantity, thickness, size, hole size/placement and finish for your custom timber brackets. . Metal Finishes; Bracket Corners and Edges; Can't find what you're looking for? CONTACT US. 715-718-0781 [email protected] CUTTING EDGE METALS, INC. 4031 East 1st Street

cnc processed parts|local cnc machine shops