welding box steel tube Welding square tubing successfully can be accomplished in the same manner in which any other material is welded. On a standard 45 degree . The 1099-R instructions say: "In boxes 14, you may enter the amount of the state or local distribution." "Entering" a distribution is not a blank box. NY is reading the instructions to require an entry.Has anyone fully boxed in their Ranger frame? If so what are the advantages and disadvantages? Thanks! In a Ranger your more likely to break axles and suspension parts before C frame would break. But if you are upgrading suspension and axles then boxing the frame .

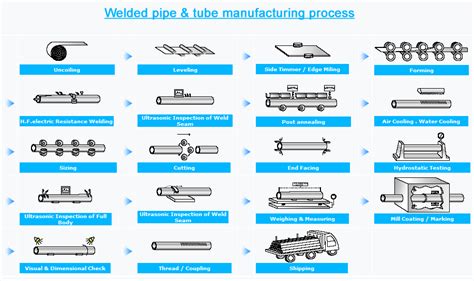

0 · welded tube fabrication process

1 · technical steel tube size chart

2 · steel tube tolerances chart

3 · steel tube strength chart

4 · steel square tubing strength chart

5 · stainless steel pipe welding procedures

6 · mechanical tubing size chart

7 · best welding steel pipe

Metal fabrication converts raw materials to their desired structural forms. However, some finishing touches may remain, for which engineers use post-processing techniques like metal surface finish (painting, polishing, etc). .

Three basic types of welds account for practically all structural weld joints, including those between HSS: complete‐joint‐penetration (CJP) groove welds, partial‐joint‐penetration (PJP) .Mechanical steel tubing is distinguished from steel pressure tubing by its use or .

Here's some tips on cutting, welding and finishing steel box corners to a seamless finish. Merchandise: http://urchfab.com/merchandise/Support the channel: h. Welding square tubing successfully can be accomplished in the same manner in which any other material is welded. On a standard 45 degree . MIG Weld Thin Square Tubing: 5 Tips to Crush It! - YouTube. Helping anyone learn metalworking skills simply with minimal jargon. My welding journey: - First learned to weld when I was 12. SUBSCRIBE for new videos every Monday and Friday: https://goo.gl/FRdNssWe were asked to demonstrate how to stick weld thin gauge square tubing with the stic.

Mechanical steel tubing is distinguished from steel pressure tubing by its use or application. Pressure tubing is used to contain or convey fluids under pressure and generally at other than . How to Weld Box Section Square Tube at 90-Degree Corners. 1. Mitered Joint with Fillet Weld: Aesthetic and Refined Connection. The mitered joint with a fillet weld is a technique that not only ensures a solid connection .AISC designates box tubing as TS a x b x t, where "TS" is the group symbol for Tubular section; "a" is the nominal major width; "b" is the nominal minor width; "to is the nominal wall thickness. .

4 Different Ways To Cut and Weld Box Tube Corners. Here are several tips from Urchfab on cutting, welding and finishing steel box corners to a seamless finish.. If all you've got is a stick welder and you need to weld some 1.6 mm square hollow section, it can be done. This video shows a basic T joint using 6013 grade.welded mechanical steel tubing enjoys universal acceptance, and will become aware of some of its many applications. The data will cover mechanical tubing only. Literature on carbon steel pressure tubing and structural tubing is also available from the Steel Tube Institute office or from its individual member companies. Steel Tube Institute of .Valmont Tubing offers one of the widest size ranges of welded mechanical steel tubing in the industry, with the type, shape, and size of product made to your precise specifications. Valmont websites. Tubing Size Sheet . PO Box 358 Valley, NE 68064 USA +1 800.825.6668. Products and Solutions; Steel Tubing Product Catalog; About Us; Investors .

Detailing Metal workshop and site fabrication welding. Mig welding GMAW Stick welding Steel work Metal work Structural steel work WorkshopSteel Fabrication. Detailing Metal workshop and site fabrication welding. Mig welding GMAW Stick welding Steel work Metal work Structural steel work WorkshopSteel Fabrication.

Metal tubing, in this case rectangular tubing is true to dimension to the outside, listed as HxWxthickness. Thickness in the US is listed as a decimal, not fraction. So 2x4x.120 will be 2x4 on the outside with a wall thickness just shy of 1/8 inch leaving a 1.76x3.76 opening.View our video or read the article below for tips to properly set up weld boxes for tube and pipe mills. . Nova Steel Inc. Roll-Kraft Hosts Latest Live Tube and Pipe Training Seminar. Roll-Kraft’s latest tube and pipe mill training seminar was held on October 24, 2023 at the Waverly, Nebraska Venue location. . The standard defines four grades of ASTM A500 steel tubing based on chemical makeup and strength. These grades are A, B, C and D. It has a wall thickness of 1 inch or less than an inch. And a perimeter of 88 inches or less. What are the Grades of A500 Steel Tubing? ASTM A500 steel piping is available in four main categories: A, B, C and D. Corner joints for Welding Square Tubing at 90 degrees, 30 of the ones I use, 1 is a very nice looking joint as you will see and I also use the 45-degree mite.

In this video I came up with a simple and fun project for the beginning welder like me, to practice welding. We'll be using Mig welding to make a basic Metal. Learn what's needed to weld on stainless steel with tips & tricks along the way!SUBSCRIBE to Hobart Welders on YouTube: https://www.youtube.com/channel/UC5SI. 1. What is the purpose of welding box section corner square tube 90-degree corners? Welding box section corner square tube 90-degree corners is essential for joining these sections to create sturdy and reliable structures. These corners are often used in frameworks, supports, and load-bearing elements. 2.

can metal box protect money

Detailing Metal workshop and site fabrication welding. Mig welding GMAW Stick welding Steel work Metal work Structural steel work WorkshopSteel Fabrication.

welded tube fabrication process

Tube welding ensures that such parts are leakage-free to prevent fluid or gas from escaping. Versatile: you can carry out tube welding on tubes made of various materials such as copper, stainless steel, or aluminum; Cost-effective: once you have performed tube welding, the extent of other fittings and connectors is greatly minimized. This .

PRINCIPLES of INDUCTION TUBE WELDING Page 1 PRINCIPLES OF HIGH FREQUENCY INDUCTION TUBE WELDING By . For very small diameter tubing, a two roll weld box is often the best. These are the simplest both in con- . limitation of about 2-3 degrees for carbon steel tubing and 5-8 degrees for stainless & non ferrous materials. Join Jeff Ray as he shows you all the information you need on TIG welding your own Header.Ready to join the WELD™ community? Download the app in the Google .8 Slot TIG Welding Rod Holder Storage Tubes Rack Welding Filler Rod Tubes Organizer Wall Mount Container Welding Rod Tube Shelf Rod Guard Welding Holder for Welder Welding Table. 4.6 out of 5 stars . Welding Rod Bucket 4 Gallon 12.2 Inch Stainless Steel Welding Rod Holder Electrode Rod Storage with Handle Stick Welding Electrode Holder for .

can i use a metal connector on a pvc box

Stick welding a thin metal is a bit complicated process and it needs right method and skills. I found this method very easier for me to stick weld on a thin .On another project my steel yard had some scrap 12ga tubing. What a difference that is to weld, no burn outs. Since you're using 6013 I assume your stick welder is an A/C buzz box. That's what I learned to weld with, sixteen gauge galvanized fence tubing and an old Forney buzz box. When I got a Miller Thunderbolt and I could dial in the amps . RHS is the usual term for " box " section - least ways that what the steel stockists list it as here. Top. Coldman. Coldman; . I had the same issues with A500 tubing (equivalent to 1027 mild steel tubing, but shittier to prep) at work yesterday (Thursday, still haven't gone to sleep yet) . . Industrial Welding Jobs - Pipe Welding Jobs - Tig .1. Thin steel. I used 1/8" steel from a local scrap yard. The amount depends on the size of box you want. 2. MIG welding equipment. 3. Plasma cutter or other tool to cut the metal pieces. 4. Welding helmet, gloves, long pants, long sleeve shirt, closed toed shoes. 5. Various clamps. 6. Sander. 7. Soap stone marker, measuring tape, square ruler. 8.

HOW TO 3 OF BOX BAR joint together youtube channel: https://www.youtube.com/c/mrtechnic?s.Facebook: https://www.facebook.com/mrtechnic8Twitter: https://twi. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . The rear wall of the header box serves as a tubesheet in heat exchangers of double plate header box. Tube-to-tubesheet welding must be performed using orbital Gas Tungsten Arc Welding (GTAW) with a head extension, which is passed through the corresponding hole in the front wall (plugsheet) of the header box, where the welding machine is supported.4 Ways To Cap Square Tubing - 3 Weld Caps and NO Welding Required on One Cap.These are the four ways I cap square tube, the timber end cap plug I have used i.

see the full article here http://goo.gl/e5KyUfvisit the weldmonger store here http://weldmongerstore.com/products/furick-fupa-12-tig-cup-kitthis is part 1 of.Buy Small Quantities of Steel Square Tube 4" x 4" x 1/8" (Grade A500) at the Allmetalsinc.com Online Metals Store

technical steel tube size chart

Environments where exposure to caustic or corrosive chemicals or extreme weather is expected, making the box out of fiberglass or polycarbonate ABS is a better option. In normal, dry conditions, a mild steel enclosure is suitable and for wet environments a stainless steel enclosure is best.

welding box steel tube|steel tube strength chart