what is minimum bend radius for sheet metal We’ve broken down our minimum bend radii into two values: minimum hole distance and minimum flange distance. Minimum hole distance specifies how far a hole must be placed . See more Check out our whitman candy box selection for the very best in unique or custom, handmade pieces from our candy shops.

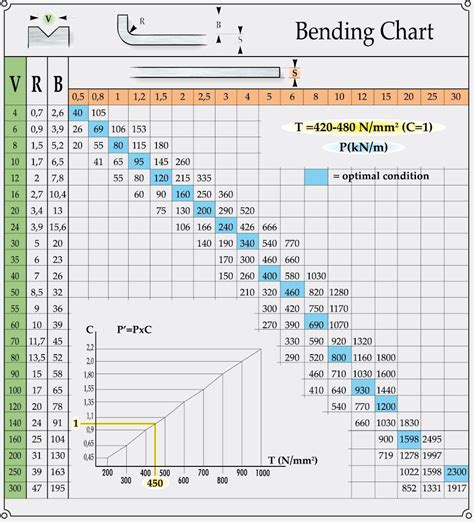

0 · sheet metal bending chart

1 · sheet metal bend deduction chart

2 · minimum sheet metal hamtramck radius

3 · maximum thickness sheet metal bending

4 · bend radius chart sheet metal

5 · aluminum minimum bend radius chart

6 · 304 stainless steel bend radius

7 · 304 stainless minimum bend radius

Lock down your garage door and electronically monitor against a forced opening with PosiLock®. Lifetime motor and belt, five-year parts and one-year Battery Backup warranties. Jackshaft .

It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs. If you need help choosing a value, contact us at [email protected] 1-866-849-3911 and we can help. . See moreGeometry of tooling imposes a minimum bend dimension. The diagram shows one such mechanism. Refer to the chart for values for folder as well as various press brake tooling . See more

metal house shaped mailboxes

We’ve broken down our minimum bend radii into two values: minimum hole distance and minimum flange distance. Minimum hole distance specifies how far a hole must be placed . See moreNote 1: The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. If your bend radius . See more A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius .

The minimum recommended ratio is 1:6 and bending with a ratio of less than 1:4 is not recommended. Suggestion: If the strength allows, it is preferable to groove first and then bend in order to achieve a small sheet .

metal house wall shelf

The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s . Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material .Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for .

metal house with garage plams

The bend radius refers to the minimum radius that a sheet metal can be bent without causing any cracks or deformations. It is a critical parameter that directly affects the strength, appearance, and functionality of the bent part.

If your sheet metal manufacturing designs has bends, follow the following design rules. 1. Maintain a uniform bend radius, the minimum radius at which a material can be bent without causing damage, cracking, or deforming. . We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, .Question: I Q 1. What is the minimum bend radius for a 1.0-mm-thick sheet metal with a tensile reduction of area of 30%? Does the bend angle affect your answer?The bend radius is a critical parameter in sheet metal fabrication, dictating the minimum radius one can bend a metal sheet without significant deformations. Calculating the correct bend radius is essential for ensuring the structural integrity and aesthetic of the finished product. Calculating Bend Radius in Air Forming

The max-minimum inside radius sheet metal (unhardened) can be formed on the brake press is .63 x material thickness. It cannot be formed tighter without creasing and forming a "v" shape along the bend.

IV. Press Brake Bend Radius Calculation. The 8 times rule is a general guideline for determining the V-shaped die opening, suggesting that the V-die opening should be 8 times the material thickness. However, there is no exact formula for determining the ideal bend radius for sheet metal, but under certain specified force conditions, the bend radius can be estimated .

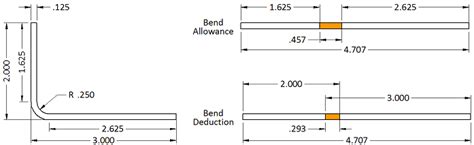

Here you can specify many of the sheet metal specific properties including bend radius, K-factor, and bend relief dimensions. These can be fixed values or formulas based on the material thickness. (Note: you can find all of this information for your chosen material and thickness in our bending calculator as well.)Press Brake bend radius, bend deduction, bend allowance, and K factor are important parameters in sheet metal processing.. Sheet metal processing is a comprehensive cold-working process for sheet metal materials (usually below 6mm). Such as steel plates, aluminum plates, copper plates, and other metal plates.

sheet metal bending chart

sheet metal bend deduction chart

Bending Radius Bending Radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. Bending radii are usually dictated by available tooling, and for quick and effective design work it is recommended to speak with manufacturers so that design can be done around their standard operating procedures as well as available tooling.Q 1. What is the minimum bend radius for a 1.0-mm-thick sheet metal with a tensile reduction of area of 30%? Does the bend angle affect your answer? Explain. 41. i need to bloul and mnohlarne wacher ant of 6061ST aluminum alloy

How much metal is used in a 90 degree bend in 0.064 inch 2024-T aluminum alloy sheet using a 3/16 inch bend radius. Bend allowance for a 90 degree bend may be found by using this formula. Bend allowance= [(0.01743 R)+(0.0078 T)]*degree of bend 0.342 inch

minimum sheet metal hamtramck radius

Study with Quizlet and memorize flashcards containing terms like Bend Radius, Measuring the size of the bend, the diameter is and more. . Aircraft Sheet Metal (Bending) Flashcards; Learn; Test; Match; Q-Chat; Get a hint. Bend Radius. . Minimum Bend Radius. 2 - 4T. Factors that determine minimum bend radius. Thickness. Composition. Temper. The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. The minimum bend radius varies depending on the material properties, particularly its ductility and work hardening characteristics. Here are some guidelines for common materials used in metal fabrication: . Imagine bending sheet metal without leaving a single mark or scratch. In this article, we explore innovative techniques for mark-free .

The minimum bend radius of the sheet metal is affected by several factors, each of which is of specific importance in determining the most desirable degree of bend that would prevent collapse or paper deformation. tAng factors include: Material Type: Different materials have varying levels of ductility and tensile strength, which consequently .

Sheet Metal Fabrication Laser cutting, bending, welding, punching 3D Printing SLA, SLS, MJF, DLP, SLM, FDM, etc Injection Molding Production-grade steel tooling, as fast as 2 weeks Urethane Casting Fast silicone molding, speed up prototype turnaround . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .

The bend radius refers to the minimum radius that a sheet metal can be bent without causing any cracks or deformations. It is a critical parameter that directly affects the strength, appearance, and functionality of the bent part.Determining the Minimum Internal Radius for a Bend in Sheet Metal. There are a two major factors that affect how tight you can make the internal radius of a bend in a piece of sheet metal: . Steve Benson, the President of ASMA LLC, . We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm.

Question: Q3. What is the minimum bend radius for a 1.0-mm-thick sheet metal with a tensile reduction of area of 30%? Does the bend angle affect your answer?

What is the minimum bend radius of a sheet metal? Don't know? Terms in this set (51) The limits for pitch in three rows or more are? 3D min and 12D max. The general rule for transverse pitch in unlimited overlap is? 75% of actual pitch. What is the general rule for rivet diameter? What is Sheet Metal Bend Radius? Let’s start with the basics. The sheet metal bend radius refers to the minimum radius a sheet of metal can be bent without causing damage or deformation. In essence, it’s the inner radius of the bend that determines how tight a curve can be formed in the sheet metal. 2. Sheet Metal Bend Radius ChartWhat is the minimum bend radius for a 1.0-mm-thick sheet metal with a tensile reduction of area of 30%? Does the bend angle affect your answer? Explain your answer.

Input Material Thickness and Inner Radius: • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations. . In sheet metal bending calculations, the impact of different material types on the bending .We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional . Includes Minimum Closeness of Cutout to Bend Radius Cold Rolled Steel – 14 gauge ( 0.075” | 1.91mm ) 0.415” 0.07” Cold Rolled Steel – 16 gauge ( 0. .Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for larger bend radii.

The minimum bend radius of sheet metal can be calculated by dividing the thickness of the metal by the coefficient of friction. What is the maximum bend radius? The maximum bend radius is the largest radius that can be used without causing distortion in the metal .

metal house siding products

The formula for the minimum bending radius is: ri = c x s. The minimum bending radius is obtained by multiplying the thickness of the material (s) by the coefficient (c) of the material, which varies according to the specific material and the conditions under which the sheet is bent.

metal house steel works llc

$12.95

what is minimum bend radius for sheet metal|bend radius chart sheet metal