what is cnc part programming A CNC programmer writes instructions that tell the CNC machine tell the machine to move in a certain direction, by a certain distance. What a . See more So I essentially have a surface-mounted junction box underneath the sink. Is this a problem? The electrical box for the disposal outlet is meant for damp locations, and all wire passing under the sink is protected by conduit.

0 · manual cnc programming for beginners

1 · different types of cnc programming

2 · cnc programming website

3 · cnc programming full form

4 · cnc programming and machining

5 · cnc machine programming and operation

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

Underground pull boxes safeguard and offer easy access to buried electrical power lines. They include concrete/cast pull boxes, non-metallic pull boxes, covers and accessories. These .

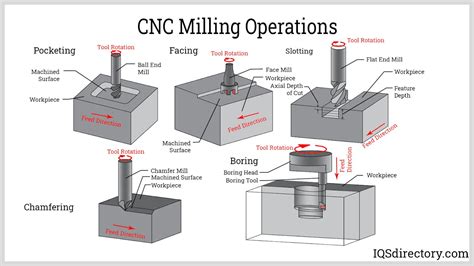

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes, and 3D printers. These CNC machines receive their . See moreCNC programming involves taking a 3D CAD model, and converting it into a CNC program with defined toolpaths (where the tool moves during . See moreCNC programmers use G-code commands to instruct CNC machines what to do. They’re called g-code because most of the letters in the . See moreThe 3 main types of CNC programming are: 1. Manual CNC programming 2. Programming with CAM software 3. Conversational CNC programming See more

A CNC programmer writes instructions that tell the CNC machine tell the machine to move in a certain direction, by a certain distance. What a . See moreCNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing . CNC part programming begins with setting up a program number and essential safety CNC part programming codes like G28 for home return, M5 for spindle stop, and M30 to end the program. Establish the working plane . The document discusses CNC part programming, including manual part programming formats and an example program for turning a part. It covers the input data and codes used in manual programming, such as .

CNC (Computerized Numerical Control) machining is a technology that allows machines to perform precise cutting, engraving, drilling, or milling operations based on preset instructions, m-code is a component of the CNC programming language used to control various functions during the machining process. This article provides a comprehensive understanding . The Process of CNC Programming. Considering the guide on how to program a cnc machine, you should know that CNC programming is the intricate process of transforming a 3D CAD model into a series of machine-readable instructions.. And to answer the questions about what is part programming in CNC machines━it’s the process of creating detailed instructions .

manual cnc programming for beginners

The first step in CNC programming is to design the part using CAD software. This involves creating a 3D model of the part, specifying its dimensions, and incorporating any necessary features or details. The CAD software provides a visual representation of the part, allowing the programmer to visualize how it will look and function. . Manual programming for a CNC mill or lathe has been the most common way to program over the years that CNC machines have been used. Manual programming is done either by hand and transferred to a computer file, or punched in by hand on the machine controller.ProsLets look at the good stuff first. Manual programming is limitless when it .Study with Quizlet and memorize flashcards containing terms like 0What is the correct order of steps for restarting a program in the middle of a toolpath?, How are part programs used on the Haas control?, How do you know which program is currently active? and more. CNC programming is one of the main contents in the preparation stage of CNC machining, which usually includes analyzing the part pattern, determining the machining process, calculating the tool path, obtaining the tool position data, creating the CNC machining program, making the control medium, proofreading the program and the part machining test.

In basic CNC program development, which part do most programmers write first? Toolpath block Manual data input, computer-aided manufacturing, and conversational are all __________.In this article, we will explain more about what CNC programming is, the software involved, its importance, and more. Explaining CNC Machine Programming. CNC programming starts with a design concept or blueprint created using computer-aided design (CAD) software. This design serves as the foundation for the part to be manufactured.

Part program . The part program refers to the section of a program which contains all the info needed for executing the cutting process carried out by a single cutting tool. The phrase ‘Part Program’ is sometimes also used to reference the complete program that is used to program a part. Below is an example of a part program that taps 3 holes. Deliverable: A G-Code Part Program created using Conversational CNC. Conversational CNC is programming g-code by asking questions of the programmer in order to create operations that are similar to the operations a manual machinist might use. It does not require the use of a CAD model or drawing.CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling and drilling. CNC programming involves writing a series of commands, typically in the form of a .

The instruction program or part program has all the necessary commands needed to control the cutting tool in the machine. For example, it has commands to control the spindle speed, transmission rate, power, etc. . D in CNC programming is a tool address character used to feed the tool diameter.Study with Quizlet and memorize flashcards containing terms like what does CNC stand for?, what is the function of CNC?, what does CNC automation control? and more. . what is the relationship between the part program and the controller? the part program generates signals to tell the motor steps and directions. Where is it used in CNC programming ? . You feed the NC program into the machine and cut the part. APT programming language example for milling around a part $$ PART SHAPE DEFINITION. STRT = POINT/ -50, .

A part program is a(n):, 2.What does a coordinate code communicate to a CNC machine?, 3.What is computer-aided manufacturing? and more. Study with Quizlet and memorize flashcards containing terms like 1.What is a part program? CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. . especially if CNC machining and its myriad of processes are part of your day-to-day activities. There’s a lot to cover on this topic, so let’s get cracking.

different types of cnc programming

Computer Numerical Control (CNC) is a method of automating control of machine tools through the use of software embedded in a microcomputer attached to the tool.With CNC, each object to be manufactured gets a custom computer program, usually written in an international standard language called G-code, stored in and executed by the machine control unit(MCU).The .

How to process CNC Programming? CNC programming is a vital aspect of the CNC machining process. It involves using the G-code language to describe the shape, process, parameters, and auxiliary information of a part. The CNC programmer writes the program using specific function instruction codes and block formats.

Then that part program is run by cnc machinist by pressing Cycle-Start, and now the control is transferred to the cnc machine control which now reads the part-program and instructs different parts of cnc machine to do the required operation. This way whole the part-program instructions are executed block by block.CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling and drilling. CNC programming involves writing a series of commands, typically in the form of a . CNC programming is the process of creating and running a program consisting of G code in a CNC machine to move the machine and control its functions. There are a large range of CNC machine types available, from industrial mills and lathes to home machines such as 3d printers, laser engravers and CNC routers.The operation of a CNC machine tool is typically controlled by a "part program" written a language known as G-code. [3] Canned cycles are similar in concept to functions in a traditional computer language, and can be compared also to G-code macros. The format for a canned cycle consists of a series of parameters specified with a letter and a .

Once the CNC program is generated, it is loaded into the CNC machine’s computer, which then controls the movement of the cutting tool, ensuring the desired part is accurately produced 4. The following are key components of a CNC program: Coordinates: Define the position of the cutting tool relative to the workpiece.

CNC part Programming : The part programming contains the list of coordinate values along the X, Y and Z directions of the entire tool path to finish the component. The program should also contain information, such as feed and speed. 4. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. .

cnc programming website

cnc programming full form

Find a lower price on an exact item? We'll match it. Some exclusions apply. Return it in store or ship it back for free. Eligibility rules apply. Delivery is on us for orders over $45. Some exclusion apply.

what is cnc part programming|basic cnc programming for beginners