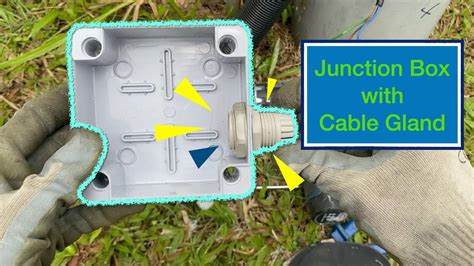

installing standard junction box One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing . Junction blocks are rectangular plates that use screws to connect each of the four service wires (from the phone co.) together with your inside wires. A junction block has four terminals that hold the wires together with screws.

0 · youtube install junction electrical box

1 · residential electrical junction box

2 · junction box installation instructions

3 · install old work electrical box

4 · install junction box in wall

5 · home electrical junction box install

6 · convert outlet to junction box

7 · arrows rc junction box setup

Corrugated metal roofing is a metal sheet that is roll formed into a metal panels. These panels are than attached to the roof with screws. Corrugated metal is an exposed fastener panel, meaning that each fastener is visible on the panel's surface. The traditional shape of corrugated sheet metal is round and wavy.

brackets autoligados metalicos

youtube install junction electrical box

A junction box is a standard electrical box that contains two or more spliced electrical cables. The box must have a removable, accessible cover. Junction boxes can be . Installing an electrical junction box is a handy skill for any homeowner to know. Check out this video where we walk you through how to install an electrical junction box step by step.. How to Install an Electrical Box in a Finished Wall. Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists.

residential electrical junction box

Install junction boxes where they are always accessible. Never install a junction box in a concealed wall or ceiling space where it cannot be accessed in the future. Junction boxes must also be covered with solid covers.

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .Pull & Junction Boxes Learn with flashcards, games, and more — for free. . When installing EMT, a standard square box with a cover can be used as an inexpensive alternative to a (n) _____. Type T conduit body. 3 multiple choice options.

I tried to install an outlet on existing junction box as below, but failed because it's too small to put in. I have 3 solutions to think. Remove junction caps and put 2 outgoing lines into backstabs and screws, so it works as junction; Buy . For more products' information visit our website product pages at UJB155 - https://enssecurity.com/universal-junction-box-ujb155-g.htmlUJB129 - https://ensse.

Standard junction boxes feature a square or rectangular design with multiple knockouts. These boxes offer: Standard sizes from 4×4 to 12×12 inches; Multiple conduit entry points; . Installation Expenses. Junction box installation takes less time, usually 30-60 minutes per unit. Pull boxes demand more planning and labor, often requiring 2-4 .Study with Quizlet and memorize flashcards containing terms like Determine the maximum number of conductors permitted for each of the following applications in accordance with Article 314. 6 AWG TW conductors in a 4 in. × 11/2 in. square box 12 AWG THHN conductors in a 411/16 in. × 11/2 in. square box 14 AWG TW conductors in a 3 in. × 2 in. × 11/2 in. device box 14 . The steps to install a vanity light junction box include turning off the power, removing the old light fixture, installing the junction box, connecting the wires, mounting the new light fixture, and testing the connections. It’s important to follow these steps carefully to avoid any electrical hazards. I am trying to replace an outdoor light. The current light has a round mount and mounts over the round service junction box on the outside of the house. (The junction boxes are not recessed.) The new lights have a rectangular mount. When I mount them over the junction box, they stick out from the wall (not surpising) and don't sit squarely.

1. How do you attach a junction box to metal studs? If you use the standard sheet metal screws through the flange to the stud, it seems very flimsey. Is there a better way to do this? 2. Since this wall is built very close to the chimney, I would only have about 1" between the junction box and the chimney. Installing a projector a ceiling junction box. Ask Question Asked 4 years, 11 months ago. . They sell junction box covers with standard knockout holes. Mechanically, what you did is fine as long as the projector weighs less than 4 pounds. If it weighs more, you need to properly tie into the fan support structure in the way that you might for . One that would allow me to pigtail inside the box but install the outlet closer to standard install height. I've seen junction boxes that have "behind the wall storage" to the side of the junction box like in the picture below, but does the same thing (or similar) exist for top down (or bottom up) wiring like I'm describing? The national average materials cost to install a ceiling outlet box is .70 per box, with a range between .47 to .94. The total price for labor and materials per box is 7.46, coming in between 1.40 to 3.52. Your actual price will depend on your location, job size, conditions and finish options you choose.

From junction boxes to work boxes, we’ll help you choose the electrical box that fits your needs. . Different electrical box sizes fit varying installation needs. . For screen reader problems with this website, please call 1-800-430-3376 or text 38698 (standard carrier rates apply to texts). Store Locator | ©2000-2024 Home Depot |A: Answer This is needed for a hard wired installation as the cord that comes with the dishwasher is only for plugging into a three prong outlet. The plug side of this is for connecting to the back of the dishwasher and the junction box at the end of it is for a hard wired connection. You will not be able to make a hard wired connection without .In this way, the guidelines can adapt to the electrical safety standard changes and stay current with technological advancements. After the NEC is reviewed, a group of experts within the electrical industry revises it to incorporate the most secure and recent methods or standards. . To ensure the stability of the junction box, you can install . New Construction applications: Junction box shall be firmly secured to studs, joists, or similar fixed structural units. Remodel applications: Do not require the junction box to be firmly secured after the mounting plates, .

The box needs an adapter ring attached to hang a standard fixture (or to mount switches, receptacles, etc.) . receptacles, etc.) By itself that is just a junction box called a "4-S" (for 4" square). Look for a 4-S to 4-O plaster . (old .

Standard Drawing, while de-signed in accordance with generally accepted engineer-ing principles and practices, is the sole responsibility of . Install Junction Boxes And Hand Holes At The Approximate Locations Shown, Or If Not Shown, No More Than 300 Feet Apart For Junction Boxes NEC specifically calls out -32 as the required thread pitch for sufficient engagement into UL-standard junction boxes and enclosures. On a stock metal box, most holes are NOT tapped to be ground holes, they are simply for nails to mount the box. However, one hole is smaller than the others and will be tapped 10-32.

Standard Junction Boxes. Standard junction boxes are the most common type and are used for general electrical connections. They come with removable covers for easy access. . Installing a Junction Box. Installing a junction box is a straightforward process, but it must be done correctly to ensure safety. Here are the basic steps: Technically metal box + (non-flexible) metal conduit = the box carries the ground, however since the bar-box connection is improvised, I would run 1 ground wire to remove all question of how the ground bar is mounted to the box. (for electrical connection must be tapped -32 screws or finer and #8 or larger, so 8-32 or 10-32). In this video we will be installing an old work round box in the ceiling, using great stuff to save money on the heating bill, and patch a small hole in the .When installing EMT, a standard square box with a cover can be used as an inexpensive alternative to a(n) _____. Type T The minimum length of a pull box with one 2" conduit and two 1" conduits entering on one side of the box and exiting at .

With standard steel 4" x 4" With standard steel 4" x 4" on-wall junction box in-wall junction box When installing the FreeSpace® DS 16S, DS 16SE, DS 40SE, or DS 100SE loudspeaker on a Bose- validated on-wall junction box, only two (2) of the four (4) screw holes of the wall mount bracket will be used. Bose has conducted extensive tests to ensure More reliable is to run one cable, cut it to length, pull it out, make a second (or more) cable, and re-run them together. If you need to wire up a complete house, then I recommend getting two boxes of cable, so you can pull two wires simultaneously. Make sure you keep enough extra length on each end of the cable. You want to route the cables .

junction box installation instructions

Cut the wire between two boxes and pull it into each of them. Run a new length of wire between, and splice in your new outlet leg from one box. It's more or less blacks to blacks and whites to whites. Junction boxes must remain accessible. Secure all cables appropriately (and within a foot of each box).

install old work electrical box

Would appreciate any advice/help on the best way to mount a Ring Floodlight circular mounting bracket to a rectangular junction box (please see pic)? Mounting a Ring Floodlight to a rectangular junction box (lights, siding, best) - House -remodeling, decorating, construction, energy use, kitchen, bathroom, bedroom, building, rooms - City-Data Forum Installing the Junction Box for Multiple Pendant Lights. Bear in mind that the junction box is the central hub for wiring multiple pendant lights. Choosing a strategic location is crucial, typically the center spot of where all lights will hang. First, fasten the junction box to a reliable support. If there isn’t a nearby stud or joist, a fan .

brake light junction box

brackets for bellaire metal lawn chair

Sheet metal is an industrial process that forms thin, flat pieces of metal, such as steel and tin, into coils. In the U.S., the thickness of sheet metal is typically specified by its gauge, which ranges from 30 gauge to about 7 gauge. Other metals like aluminum, brass, copper, steel, tin, nickel, and titanium can also be used in sheet metal.

installing standard junction box|residential electrical junction box