cnc lathe machine operations The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by removing material from it. Choose from our selection of metal U-channels, including low-carbon steel U-channels, architectural 6063 aluminum U-channels, and more. In stock and ready to ship.

0 · turning operations on lathe machine

1 · parts of cnc lathe machine

2 · cnc lathe work

3 · cnc lathe process

4 · cnc lathe parts

5 · cnc lathe machine working

6 · centering operation on lathe machine

7 · center lathe operations

Perforated metal sheets, also known as a perforated screen or perforated metal, are made up of coils of stainless steel, aluminum, or mild steel. That has been uniformly or mechanically .

The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by . What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe.

The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by removing material from it.

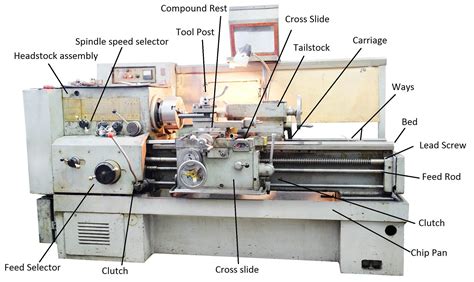

electrical boxes for icf construction

In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece about an axis to perform different operations such as turning, facing, taper turning, knurling, grooving, parting off, thread cutting, reaming, etc.Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various types of CNC lathe machines and how they differ in terms of capabilities and applications. What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by . What are the Key Components of a CNC Lathe Machine? A CNC lathe is an assembly of intricate components, each playing a crucial role in its operation. Understanding these components gives you a deeper insight into how these machines achieve such high levels of precision and efficiency.

This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols.

turning operations on lathe machine

With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process. When it comes to figuring out how to operate a CNC lathe, in addition to being taught the basics through formal training, it is important to have the operator’s manual on hand. If you’ve acquired your equipment from a used CNC lathes dealer, you may need to source the operator book from the manufacturer or online.

CNC lathe machines operate on CNC programming principles, automated tool movement and positioning, material removal process, and precision machining. These principles enable the machine to produce high-quality components efficiently with accuracy and consistency. What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe.

The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by removing material from it.

In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece about an axis to perform different operations such as turning, facing, taper turning, knurling, grooving, parting off, thread cutting, reaming, etc.Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various types of CNC lathe machines and how they differ in terms of capabilities and applications.

What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by .

What are the Key Components of a CNC Lathe Machine? A CNC lathe is an assembly of intricate components, each playing a crucial role in its operation. Understanding these components gives you a deeper insight into how these machines achieve such high levels of precision and efficiency. This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols. With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process.

When it comes to figuring out how to operate a CNC lathe, in addition to being taught the basics through formal training, it is important to have the operator’s manual on hand. If you’ve acquired your equipment from a used CNC lathes dealer, you may need to source the operator book from the manufacturer or online.

electrical boxes homes paradise palms

parts of cnc lathe machine

cnc lathe work

electrical boxes shortage

cnc lathe process

Sheet metal finishing applies protective or decorative coatings to metal parts through chemical, mechanical, or electrical processes. The metal surface undergoes preparation, treatment, and final coating to achieve specific .

cnc lathe machine operations|turning operations on lathe machine