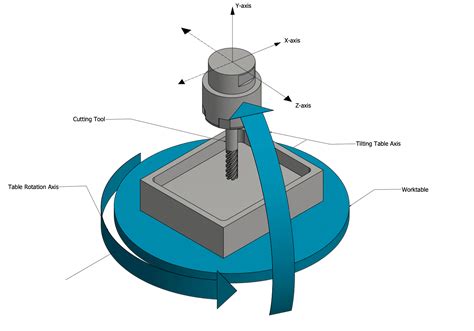

cnc 3 axis machining What is 3-Axis CNC Machining? A 3-axis CNC machine is the most basic type of CNC machine, moving the tool or part along three primary axes: X, Y, and Z. This type of machining is commonly used for simple and flat geometries. Understanding Each Axis and How It Works. X-Axis: Moves the tool left and right. Y-Axis: Moves the tool forward and backward. Vertical siding built from steel is recognized as the most durable, low-maintenance option for homeowners, regardless of region. Not only does steel siding have a Class A Fire Rating and Class 4 Impact Rating, but it is also crafted in a .

0 · small 3 axis cnc mill

1 · axis identification in cnc machine

2 · 3 axis vs 5 mill

3 · 3 axis vertical milling machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc milling machine

6 · 3 axis cnc machine price

7 · 2.5 axis milling vs 3

The VDM series of vertical lathes offers modern, conventional solutions for machining large workpiece diameters and heavy workpiece weights. Their design enables particularly easy and safe loading and .

A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move . 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.

A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move either horizontally (X-Y axes) or vertically (Z axis) to control the cutting depth.What is 3-Axis CNC Machining? A 3-axis CNC machine is the most basic type of CNC machine, moving the tool or part along three primary axes: X, Y, and Z. This type of machining is commonly used for simple and flat geometries. Understanding Each Axis and How It Works. X-Axis: Moves the tool left and right. Y-Axis: Moves the tool forward and backward.3-Axis CNC Machining. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

Explore the intricacies of 3-axis CNC machining with Rally. Dive into techniques for precision and custom solutions in various industries. 3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe.Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle. What is 3-axis CNC machining? Learn about the basics of three axis milling machines and their role in making milled parts.

The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously. Depending on your machining center, you can upgrade to more axes if needed, at an additional cost. A 3-axis machine is a CNC machine that can mill on 3 different paths: vertically, horizontally, and diagonally. Having 3 axes allows it to mill 3-dimensional objects with relative ease. What Are the 3 Axes on a Milling Machine?

3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move either horizontally (X-Y axes) or vertically (Z axis) to control the cutting depth.What is 3-Axis CNC Machining? A 3-axis CNC machine is the most basic type of CNC machine, moving the tool or part along three primary axes: X, Y, and Z. This type of machining is commonly used for simple and flat geometries. Understanding Each Axis and How It Works. X-Axis: Moves the tool left and right. Y-Axis: Moves the tool forward and backward.

3-Axis CNC Machining. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.Explore the intricacies of 3-axis CNC machining with Rally. Dive into techniques for precision and custom solutions in various industries.

3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe.Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle. What is 3-axis CNC machining? Learn about the basics of three axis milling machines and their role in making milled parts.

small 3 axis cnc mill

The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously. Depending on your machining center, you can upgrade to more axes if needed, at an additional cost.

30 degree metal corner brackets for pergola

axis identification in cnc machine

3 axis vs 5 mill

You should have a junction box between the harness and the stator wires. It keeps crud out and insulates the connections. No idea which regulator is best without seeing a better .

cnc 3 axis machining|axis identification in cnc machine