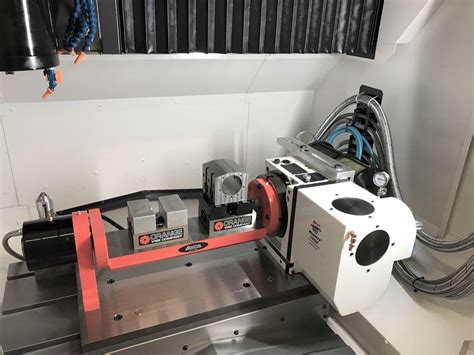

4 axis cnc mill parts 4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. Schlemmer Brothers Metalworks specializes in custom sheet metal fabrication. With state-of-the-art equipment, we have a wide range of capabilities including, laser cutting, machining, welding, bending, and much more.

0 · hobby 4 axis cnc machine

1 · cnc 4th axis for sale

2 · 4th axis rotary cnc

3 · 4 axis hobby cnc

4 · 4 axis desktop cnc mill

5 · 4 axis cnc mill cost

6 · 4 axis cnc machine price

7 · 4 axis cnc machine cost

The W axis is an additional axis on a CNC lathe machine that controls the movement of the secondary spindle. It is a linear axis that runs along the same line as the Z axis, but it is offset. The W axis is used to move the secondary spindle towards or away from the primary spindle.

hobby 4 axis cnc machine

4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. 4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials . More specific, milling on a 4-axis CNC machine gives us the possibility to machine holes and cavities at different angles. In addition, we can mill components while they are. 4 Axis CNC machines find widespread use across various industries, underscoring their versatile applications: Aerospace: The production of parts such as turbines, propellers, .

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. 4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials and part sizes.

4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more intricate cuts and contours.More specific, milling on a 4-axis CNC machine gives us the possibility to machine holes and cavities at different angles. In addition, we can mill components while they are. 4 Axis CNC machines find widespread use across various industries, underscoring their versatile applications: Aerospace: The production of parts such as turbines, propellers, and antennas that require complex geometries and high precision is .The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece.

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to .With a 5-axis machine, the X, Y, and Z-axes are similar to a 3-axis machine layout. The table then rotates along the A-axis, as it does with the 4-axis. However, the 5-axis machine involves the pivoting action at the joint of the table, followed by rotation . There are two types of 4-axis CNC machining: indexing and continuous. Index 4-axis CNC machining is when the 4th axis (A-axis) rotates whilst the machine is not cutting material. Once the correct rotation is selected, a brake is .

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup.

4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials and part sizes.

4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more intricate cuts and contours.

More specific, milling on a 4-axis CNC machine gives us the possibility to machine holes and cavities at different angles. In addition, we can mill components while they are.

4 Axis CNC machines find widespread use across various industries, underscoring their versatile applications: Aerospace: The production of parts such as turbines, propellers, and antennas that require complex geometries and high precision is .The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece.Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to .With a 5-axis machine, the X, Y, and Z-axes are similar to a 3-axis machine layout. The table then rotates along the A-axis, as it does with the 4-axis. However, the 5-axis machine involves the pivoting action at the joint of the table, followed by rotation .

cnc 4th axis for sale

cnc machining sterling hts mi

Orbit Industries' 4-11/16" Square (5S) Boxes and Extensions Rings are used to install lighting fixtures, switches, and receptacles in ceilings and walls. Our selection includes 1-1/2", 2-1/8", 2-1/2" depths and multiple 1/2", 3/4", 1" and 1-1/4" knockouts, with both welded steel and drawn steel construction.

4 axis cnc mill parts|4 axis cnc machine cost