sheet metal arc welder Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more $36.98

0 · what is a smaw electrode

1 · shielded metal arc welding wikipedia

2 · shielded metal arc welding pdf

3 · shielded metal arc welding electrodes

4 · manual shielded metal arc welding

5 · explain shielded metal arc welding

6 · basic shielded metal arc welder

7 · bare metal arc welding

NEMA enclosures and boxes are weatherproof and watertight, protecting sensitive equipment in harsh industrial environments. NEMA electrical enclosures come in a variety of materials— ranging from plastic to metal — and meet or exceed NEMA standards based on .

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See moreNow that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more

Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted . Stick welding of sheet metal shall be carried out using AWS A5.1/A5.1M E6013 (CWB/CSA W48-06 E4313) type electrode of diameter 5/64 inch or 2.0 mm. E6013 types electrode offer very good arc stability, easy-to . Arc Welding. Minimizing burn-through and distortion is essential to obtaining a good weld when gas metal arc welding thin-gauge materials. Gas metal arc welding (GMAW) is an effective method for joining light-gauge .

6 Methods of Sheet Metal Welding. Now, let’s take a comprehensive look at some methods for melding metal sheets. 1. MIG Welding. Metal Inert Gas welding (MIG), also known as Gas Metal Arc Welding. It . Plasma Arc Welding. Plasma Arc Welding (PAW) resembles TIG welding. Here, a tungsten electrode is used alongside a plasma gas—commonly argon—and a shielding gas to protect against contaminants. PAW offers you a .Like other welding methods, you won't need the most powerful Stick welder to weld thin sheet metal. Instead, you can do it with a YesWelder ARC-125DS DC Stick welder, rated at 20-125 amps with an easy arc start technology. This .

Sheet metal welding is a crucial fabrication process because it is one of the simplest ways to join cut-out pieces of metal sheets to create the desired shape. In Sheet metal welding, the mating surfaces are subjected to . Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals.D9.1/D9.1M:2018 SHEET METAL WELDING CODE Member Price: .00 Non-Member Price: .00 This code covers the arc and braze welding requirements for nonstructural sheet metal fabrications using the commonly welded metals .There is no hard and fast rule with the thickness under which you shouldn’t use stick welding.But there is a fair idea of what constitutes a thin metal and below which using stick welding might become difficult. A lot of people consider .

Stick welding, also known as shielded metal arc welding (SMAW), is a popular technique for fusing metals using an electric arc. It is a versatile and cost-effective method, making it a top choice for both skilled welders and DIY .Sheet metal welding is a process where the welder uses an electric arc to join two pieces of metal together. Welders usually wear protective equipment, including glasses and masks that protect them from sparks or hot particles flying out during operation.

7 Important Methods of Sheet Metal Welding MIG Welding of Sheet metals. MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular method of sheet metal welding due to its ease of use, control of weld deposit (using tack welding or continuous welds) and versatility. Related Reading: mig welding sheet metal settings with Charts Metal inert gas (MIG) welding is an arc welding method typically used on large parts m a d e of thick material, such as structural steel parts. With this method, we feed a continuous solid wire electrode through a we lding gun into a weld pool to join two pieces together.. Considerations for MIG welding 8. Common Welding ProcessesCommon Welding Processes • GMAW- Gas Metal Arc Welding, sometimes call Mig uses the heat of an electric arc between a continuous bare wire filler metal electrode and the work. Shielding is obtained entirely from an externally supplied inert gas (argon or helium) or reactive gases (C02 o 02) or a combination thereof. Sheet metal welding is a multifaceted craft that requires applying numerous techniques. Acquiring the requisite knowledge and skills is imperative to perform welding with optimal outcomes. . MIG welding (Gas Metal Arc welding) is a widely recognized technique. This method generates a pool of molten wire by employing a solid wire electrode in .

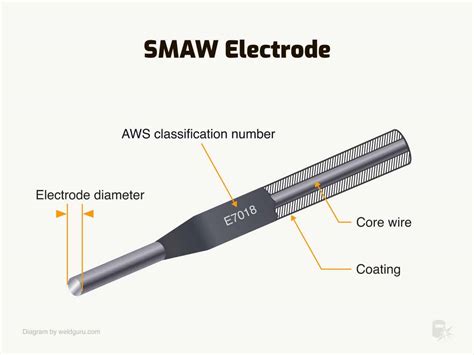

Shielded metal arc welding. Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding [1] or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld.. An electric current, in the form of either alternating current or direct current from a welding power . 6 Methods of Sheet Metal Welding. Now, let’s take a comprehensive look at some methods for melding metal sheets. 1. MIG Welding. Metal Inert Gas welding (MIG), also known as Gas Metal Arc Welding. It involves feeding a continuous solid wire electrode into the weld puddle with a welding gun. Welding sheet metal is a very critical process within the modern concept of manufacturing. The construction of metal structures, pipelines, and tanks is among the most common applications for sheet metal welding. Though the process is rather straightforward, it can be complex to achieve quality and efficiently weld thin sheet metals. Understanding the key .

hvac sheet metal jobs near me

Our sheet metal welding services provide consistent, reliable welds, delivered on time. Choose from manual or robotic welding. . large or complex weldments. These Gas Metal Arc Welding (GMAW) stations optimize speed and accuracy. More recently the addition of a Miller/Panasonic Performarc Cell adds capacity of robotically welded parts.

what is a smaw electrode

Sheet metal welding is a process that seems relatively simple at first glance – connecting several metal parts with the help of high temperatures and filler material. . MIG welding (can also be called Gas Metal Arc welding) uses a solid wire electrode in a welding tool to create a pool of melted wire which then becomes the filler material .

thin sheet metal arc welding, thin plate welding with two different electrode sizeshow to weld thin metal correct??? this is the technique of welding thin m.Welder Performance Qualification. SCWTTC is an independent testing facility that is approved to administer Weldor Performance Qualification to several codes including ASME Section IX Pressure Vessel, API 1104 American Petroleum .However, some practical advice might help you with higher gauge sheet metal. Stick Welding Equipment To Weld Thin Metal Like other welding methods, you won't need the most powerful Stick welder to weld thin sheet metal. Instead, .

hv battery power distribution box

Gas Metal Arc Welding (GMAW), commonly known as MIG (Metal Inert Gas) or MAG (Metal Active Gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode . A 70 amp arc welder can weld stainless steel that’s 1/8-inch thick or 18-gauge. It is perfect for welding. Boat trailers; Wrought iron; Automotive sheet metal; An arc welder can be a useful tool to have around the house as it can weld almost anything as long as you take care of the material and thickness of the metal sheet being welded. There are some excellent sheet metal welders available, and our five reviews are based on the best welding machines for your money available online. The best TIG machine for sheet metal welding is the PRIMEWELD TIG225X 225 Amp IGBT AC/DC TIG Welder. It’s capable of welding at very low amps for fine welding and has a broad range of settings .From my experience as a welder, the YESWELDER TIG-205 DS HF TIG/Stick/Arc TIG Welder is the best welder for metal sheet welding.. I am a welder with a great deal of familiarity with metal sheets welding. When it comes to metal sheets welding, a lot of practice is needed on the right welder to deliver an excellent job.

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. 6011 Vs 6013 Which ROD and Polarity is BEST for WELDING SHEET METAL? Have you ever wondered what the difference is between 6011 and 6013 electrodes and what. The name gas metal arc welding also remembers MIG welding. The MIG welding process melts filler material by utilizing an electric arc to join base metal pieces altogether. . In sheet metal welding, this surface appears to be the simplest and easiest to work with because of the flat position. The welding is performed from the upper surface and .Highest Standard Fabrication & Welding . Aberdeen Sheet Metal are very experienced in ensuring projects are delivered, on time, from design to completion. We take client drawings and specifications producing bespoke products and assemblies to the highest standards for our client base. . Welding: TIG, MIG & ARC . ASM works with a range of .

How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten. Ditch a 1/8-inch tungsten electrode for something much smaller, like 1/16-inch tungsten — it will give you a lot more control over the whole process, and it is more forgiving in . For most spot welding processes by using an arc welding machine, an Eastwood’s Spot Weld Gun can be used on the most stick or arc welders. It uses a current of 60 amps or even less. This ensures that those light gauge sheet metal can . Also, if you need to minimize the amperage low enough to MIG weld light sheet metal butt joints, it will do so comfortably without blowing through the sheet like a tidy TIG welder. . The Forney Easy Weld 298 90-amp Arc Welder is the best choice if you’re on a low budget but still want a decent stick welder for light welding. It’s not .

shielded metal arc welding wikipedia

A compact fuse block without bussing, the HWB60 Hard-Wired Waterproof Power .

sheet metal arc welder|bare metal arc welding