round bending sheet metal Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis. From its start as Wichita Sheet Metal Works in 1909, WSM Industries has grown to become the Midwest’s regional leader in HVAC supplies and custom metal fabrication, serving a 10-state area through 6 different locations.

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

There are some 1960s-era steel boxes here that don't even have the 10-32 threaded hole for a ground screw! For those boxes, you can use a special clip to attach the ground wire. Also, it's against code to use the same screw that attaches the .

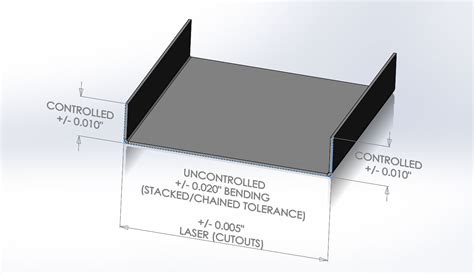

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet . Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final .

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a .You can do a lot with only a handful of tools. Even still, it can be pretty easy to mangle if you don’t use the right technique. Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working .

types of bending sheet metal

(A press brake is a simple machine employed in sheet metal bending processes, it forms desired bends on the sheet by working to clamp the sheet metal in position for press between the punch and the die) Roll Bending. . Bend allowance is a critical factor in the sheet metal bending process, particularly for materials like aluminum. It accounts for the material stretch that occurs during bending, ensuring accurate final dimensions. Here, . Mophorn 24 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 16 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers - Amazon.com . Sheet Metal .

UB-100A Heavy-Duty Universal Bender, Sturdy Design Hot and Cold Sheet Metal Bender, High Accuracy Flat, Round, Square Metal Bar Bender . Bending angle up to 120° Stop rod helps repeatable bending; Eccentric quick action cam lever material clamp; Round, square and metal bar bender

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, . Discover how to bend sheet metal with our guide on the 6 main bending techniques, including bottoming and coining, and find the best method for your project. . Roll benders are mainly used when one wants to bend metal sheets into round or curved shapes. They employ some rollers to start forming the metal into the right curve gradually. Learn how to make rounded bends with a sheet metal brake in this informative video tutorial. The part, that is shown in the Picture, looks like a 'sheet metal part. There you have bended and flattened state of the part. So maybe, you could 'simulate' your rubber part with sheet metal application. Then there is also Global Shaping (Edit/Surface). Since you are using NX6, I don't know how good it was in that version. In NX8.5 works Quite .

If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with. Figure 1-18 Z-shaped step bending. VI. Bending by Press Brake Machine. There are two categories of bending machines: ordinary bending machines and CNC bending machines. CNC bending machines are typically used for sheet metal bending in communication devices due to the need for high precision and the irregular shape of the bend.. The basic principle of the . In the realm of sheet metal fabrication, round bending machines have revolutionized the shaping of sheet metal into cylindrical or curved components. With continuous advancements, these machines now boast an array of innovative features that enhance their capabilities, efficiency, and precision. This article explores the groundbreaking features .

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, . Enter sheet round bending machines, the masterminds behind the seamless curves that shape countless industries. From automotive marvels to aerospace wonders, these machines empower manufacturers to create structural components and aesthetic masterpieces alike. . Other Metalworking Techniques- Why Choose a Swaging Machine for Sheet Metal? . In the realm of metalworking, sheet round bending stands as a cornerstone technique, transforming flat sheets into intricate cylindrical forms. However, the choice of materials employed in this process profoundly influences the outcome and performance of the final product. 1. Steel: The Versatile Workhorse

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is .

I am new to sheet metal, and am trying to model foam as a sheet metal. I made a new rule based on steel and changed its thickness to 0.5 inches, and its k-factor to 0.0296 based on research I found. But the flanges that bend towards each .Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding. Sheet metal processing is widely used in the fields of machinery, electronics, automobiles, aerospace, and construction, and is an important manufacturing technology. An .The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part stretches.

Sheet round bending machines are versatile tools used in various industries, including metal fabrication, construction, and automotive manufacturing. They are designed to bend sheet metal into cylindrical shapes, allowing for the creation of a wide range of parts and components. However, it is important to follow proper safety precautions when . A Step-by-Step Guide to Sheet Round Bending Machines. In the realm of metal fabrication, sheet round bending machines are indispensable tools for creating cylindrical and curvilinear components. Their precision and efficiency make them ideal for a wide range of industries, including automotive, aerospace, and construction.

sheet metal bending standards

In the realm of sheet metal fabrication, where precision bends and flawless contours reign supreme, the choice of a sheet round bending machine can make all the difference. This comprehensive guide will illuminate the path to selecting the perfect bending companion, empowering you to create intricate shapes and impeccable finishes with .

Finally, make sure the sheet is filed down smoothly, because otherwise you may get cracks in the metal. Place Forms and Sheet in Vise: Your form blocks should have the exact shape for bending your metal angle. When you clamp the sheet metal into the vise’s grip, make sure the bend lines on your blocks and sheet match up.Shop VEVOR 12.6 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 22 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers at lowest price, 2-day delivery, 30-day returns. Shop now at VEVOR.This video is about edge bending processes used on sheet metal.Sean Duke Bernadas BSECE 1-A TUPVPhoto by Ryutaro Tsukata from PexelsPhoto by Scott b from.

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, . Hello everyone !This is the viewers requested video so support me for this series.If u wanted to send me some objects to draw which looks difficult to you th.

cnc milling auto spare milling parts factories

sheet metal bending near me

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers .

round bending sheet metal|sheet metal bending guidelines