brass cnc machining parts Machinists refer to this alloy as commercial bronze. Despite the name, its constituent still makes it a brass alloy due to its higher copper content. It has a good machinability rating, . See more Everlast’s PowerMTS 251Si welder is their latest fourth-generation digitally controlled multi-process inverter welder and in my opinion the best welder for auto body. As .

0 · machinability of brass

1 · is brass easy to cut

2 · copper and brass machine shops

3 · cnc machine for brass parts

4 · cnc machine for brass

5 · cnc brass parts

6 · brass machinability chart

7 · brass against the machine coplot

Essential tools for bending sheet metal include a brake, mallet, and vise. These tools vary in use and complexity, allowing everything from simple bends to intricate designs. Detailed Guide to Using a Brake

Machinists commonly refer to this alloy as free machining brass. It is the most common brass grade used in machining. It is renowned for its high machinability and tensile strength. Its high machinability is attributed to its lead content which makes up about 3% of its constituents. Machinists use it for machining . See more

Machinists refer to this grade as the red brass or Nordic brass. It also has moderate strength and good anti-rust properties. The C230 is popular for its season-breaking and . See moreMachinists refer to this alloy as commercial bronze. Despite the name, its constituent still makes it a brass alloy due to its higher copper content. It has a good machinability rating, . See more

eMachineShop has machined brass parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. .

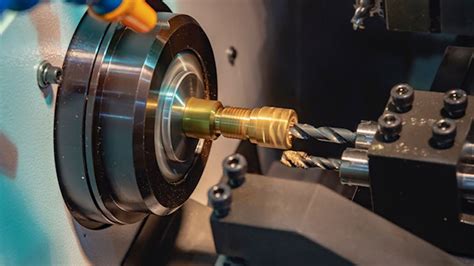

In this CNC machining brass guide, we’ll examine the properties of brass and the various brass grades used for custom brass parts. We’ll also review the applications of brass manufacturing and the factors to consider when picking brass for a machining project.eMachineShop has machined brass parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA. No Minimum Order Quantity. 100% Quality Guaranteed. cnc turning machined brass parts. Milling: Brass is placed on a milling machine, where the tools are responsible for cutting and shaping, with various tool shapes and sizes achieving complex machining requirements.

In this guide to CNC machining, you'll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production. We carry two brass alloys: C260 and C360. Brass is a weather and corrosion resistant metal with tensile strength similar to mild steel. It's also an easy to machine material.Specialized in custom-made quality Brass turning parts and machined parts. Precision machining components according to customers' specifications & industry standards. Brass machining: Create high-precision CNC parts for diverse fields. Explore brass grades, applications & key considerations.

We offer a complete CNC machining service for brass parts and can produce complex Brass parts in Brass C360. Brass parts are great for applications that require high strength, corrosion resistance, a low friction coefficient, electrical conductivity and overall versatility. Brass CNC turning involves the use of a lathe to create cylindrical parts by cutting away brass material from a workpiece. Brass and its alloys are relatively easy to machine, have good corrosion resistance, and are aesthetically pleasing. In this guide to CNC machining brass, we will look at the properties of brass and the various brass grades used for custom brass parts. We will also review the applications of brass manufacturing and factors to consider when selecting brass for your machining projects.Brass, a mix of copper and zinc, is highly valued as raw material for CNC machining in many industries. Its toughness, low friction, and resistance to wear make it perfect for CNC machined brass parts. Brass is widely used for making precise components, especially in milling and turning.

In this CNC machining brass guide, we’ll examine the properties of brass and the various brass grades used for custom brass parts. We’ll also review the applications of brass manufacturing and the factors to consider when picking brass for a machining project.eMachineShop has machined brass parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA. No Minimum Order Quantity. 100% Quality Guaranteed.

machinability of brass

cnc turning machined brass parts. Milling: Brass is placed on a milling machine, where the tools are responsible for cutting and shaping, with various tool shapes and sizes achieving complex machining requirements.In this guide to CNC machining, you'll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production. We carry two brass alloys: C260 and C360. Brass is a weather and corrosion resistant metal with tensile strength similar to mild steel. It's also an easy to machine material.Specialized in custom-made quality Brass turning parts and machined parts. Precision machining components according to customers' specifications & industry standards. Brass machining: Create high-precision CNC parts for diverse fields. Explore brass grades, applications & key considerations.

local 25 sheet metal wages

We offer a complete CNC machining service for brass parts and can produce complex Brass parts in Brass C360. Brass parts are great for applications that require high strength, corrosion resistance, a low friction coefficient, electrical conductivity and overall versatility. Brass CNC turning involves the use of a lathe to create cylindrical parts by cutting away brass material from a workpiece. Brass and its alloys are relatively easy to machine, have good corrosion resistance, and are aesthetically pleasing.

In this guide to CNC machining brass, we will look at the properties of brass and the various brass grades used for custom brass parts. We will also review the applications of brass manufacturing and factors to consider when selecting brass for your machining projects.

local 85 sheet metal union

is brass easy to cut

copper and brass machine shops

When welding thinner metals, such as less than 5 mm diameter, choosing the right welding rod is crucial for precise control over heat input and for producing cleaner welds. A correct Stick welding electrode will be compatible with the tensile strength of the metal to avoid unwanted cracking or damaging issues.

brass cnc machining parts|copper and brass machine shops