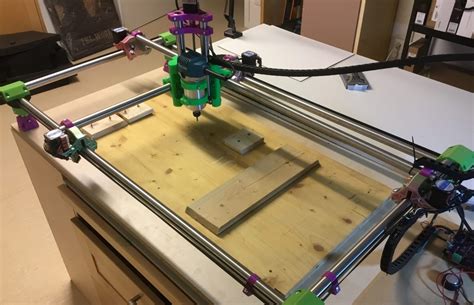

building my cnc router part 2 Trying to build my one CNC router, as cheap as possible. Many of the classic vintage pieces from the 1950s and 1960s proved so popular that they are still manufactured today. The giveaway is obviously if you find more modern vinyl or PVC boxes but sometimes replicate metal lunch boxes are still made. Some examples, include Disney School Bus, Hopalong Cassidy and the Roy Rogers metal lunch boxes. In .This does not include a thermos but does include a spinner and four round game pieces (all with magnets on back) to play the game on the back of the box.This is a colorful and shiny box with .

0 · make your own cnc machine

1 · homemade cnc router plans free

2 · homemade cnc router machine

3 · do it yourself cnc machine

4 · cnc router homemade video

5 · build your own cnc router

6 · build your own cnc machine

7 · build your own cnc

Metal Bread Box, Vintage Bread Container for Kitchen Countertop, Roll Top Bread Storage Holder, 1950s Farmhouse Rustic Bread Dispenser Basket for Dry Food Save, 11.8" L x 10" W x 6.7" H

This is a multi-part instructable that demonstrates how to build a CNC Router (a computer controlled router) from scratch. CNC Machines can come in many . This video is part 2 in a 4 part series on building a new CNC Router. This video covers the design and the machining of the Z-Axis.Check out the playlist for. Trying to build my one CNC router, as cheap as possible. In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural .

This document is a multi-part tutorial for building a CNC (computer numerical control) router from scratch. It summarizes the steps taken in part 2, which includes constructing the y-axis assembly to move the router vertically.

I have created 2d drawings of all the parts with complete dimensions and specs, details on how to build each part, a complete parts and tools lists with prices and links, a basic wiring diagram and an explanation of the design.When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of .

And here is the materials' links: Original 3018 CNC Control Board: https://bit.ly/2ZurTpl.more. Hello friends, in this video i continue the building of my diy cnc router. You can find.This is a multi-part instructable that demonstrates how to build a CNC Router (a computer controlled router) from scratch. CNC Machines can come in many shapes and sizes. Just look at these cool instructables on building a CNC.

make your own cnc machine

This video is part 2 in a 4 part series on building a new CNC Router. This video covers the design and the machining of the Z-Axis.Check out the playlist for.Trying to build my one CNC router, as cheap as possible. In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

This document is a multi-part tutorial for building a CNC (computer numerical control) router from scratch. It summarizes the steps taken in part 2, which includes constructing the y-axis assembly to move the router vertically.

I have created 2d drawings of all the parts with complete dimensions and specs, details on how to build each part, a complete parts and tools lists with prices and links, a basic wiring diagram and an explanation of the design.

When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: .Last week I started building an enclosure for my 3018-PROVer router and I finished the week with the bottom or "tub" of the enclosure built. This week I focussed on building a lid for the enclosure to keep the noise and dust down while the router was in operation. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know. And here is the materials' links: Original 3018 CNC Control Board: https://bit.ly/2ZurTpl.more. Hello friends, in this video i continue the building of my diy cnc router. You can find.

This is a multi-part instructable that demonstrates how to build a CNC Router (a computer controlled router) from scratch. CNC Machines can come in many shapes and sizes. Just look at these cool instructables on building a CNC.This video is part 2 in a 4 part series on building a new CNC Router. This video covers the design and the machining of the Z-Axis.Check out the playlist for.Trying to build my one CNC router, as cheap as possible. In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

This document is a multi-part tutorial for building a CNC (computer numerical control) router from scratch. It summarizes the steps taken in part 2, which includes constructing the y-axis assembly to move the router vertically.I have created 2d drawings of all the parts with complete dimensions and specs, details on how to build each part, a complete parts and tools lists with prices and links, a basic wiring diagram and an explanation of the design.When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: .Last week I started building an enclosure for my 3018-PROVer router and I finished the week with the bottom or "tub" of the enclosure built. This week I focussed on building a lid for the enclosure to keep the noise and dust down while the router was in operation.

metal dog show tack box

metal door jamb house pic

Up for your bidding pleasure is this vintage Bauer & Black metal advertising first aid kit box, empty medicine cabinet case box. This first aid box is in good used condition for its age. The kit looks as though it was used very hard. The metal case measures 13 1/2" wide,8 1/2" wide and 2 3/4" deep.

building my cnc router part 2|do it yourself cnc machine