cnc milling and drilling part A: The critical components of a CNC drilling machine include a spindle for holding the rotating drill bit, a workpiece table, a control panel, and control axes for motion. Other . $9.49

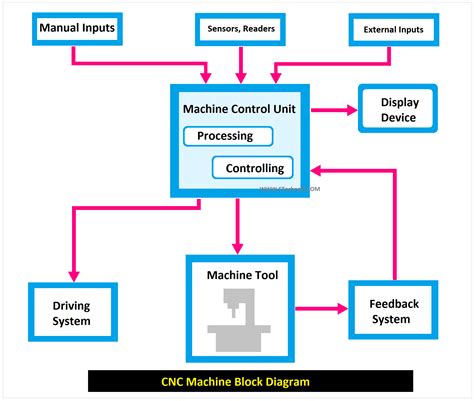

0 · schematic diagram of cnc machine

1 · milling machine parts diagram

2 · homemade cnc parts

3 · cnc milling machine parts names

4 · cnc mill parts diagram

5 · cnc mill diagram

6 · cnc machine parts list pdf

7 · cnc horizontal milling for dummies

Winston Metal Cigarette Show Case/Shelf, Metal Frame, Hanging Hooks, 25-1/2" Width, 5" Depth, 22" Height, (QTY-1)

CNC Milling and Drilling are two distinct processes. In CNC drilling, the primary aim is to drill a hole in the workpiece. The rotating tool bit moves in a single direction to achieve that.

CNC drilling and milling both are cost-effective manufacturing methods. They justify the cost with precision, complexity, and rapid turnaround capabilities. However, CNC milling processes are slightly costlier in a head-to . A: The critical components of a CNC drilling machine include a spindle for holding the rotating drill bit, a workpiece table, a control panel, and control axes for motion. Other . The tool changer is a critical component of a CNC mill, serving as the mechanism that automatically switches between different tools during the machining process. This feature is essential for complex operations requiring .

Some of the applications of CNC milling are: It is extensively used to machine flat parts. Flat parts are easy to machine and this process can be performed on the 3-axis CNC milling machine. Some of the variable angle .CNC Machining Parts Supplier, Turning Parts, Milling Parts Manufacturers/ Suppliers - Ningbo Yizhong Hardware Products Co., Ltd. Menu Sign In. Join Free. For Buyer . High Precision Custom Stainless Steel Titanium Mechanical Part CNC Machining Includes Drilling Wire EDM for Service Companies. USOEM Precision Custom CNC Machined Metallic Processing Machine Service Aluminium Auto Motorcycle Part CNC Machinery Milling Drilling Turning CNC Machining Parts. US$ 0.1-2.3 / Piece. 1 Piece (MOQ) Dongguan Hangjia Metal Technology Co., Ltd. Dongguan Hangjia Metal Technology Co., Ltd..10-1.00 / Piece. 100 Pieces (MOQ)Get an instant custom parts quote on our CNC Milling Services. 3, 4 and 5-axis machining capabilities. We produce your parts as fast as two days. . Learn how to control costs, streamline the design and machining process, and ensure quality CNC drilling, milling, and turning outcomes. Thank you for downloading! Please check your email for the . It is the most widely used of the mechanical machining processes, others being CNC turning and CNC drilling. Parts of a CNC Milling Machine. To better understand the process of CNC milling, it is necessary to know the parts of a CNC mill. Parts of different milling machines differ by manufacturer, type, and capacity.

Whether you’re diving into the details of making parts or creating products that need holes in just the right spots, CNC drilling is a crucial part of the process. Even though it’s important, not many people know much about precision CNC drill machines, which can confuse them about how these essential tools work.In this article, we’re going to explain how CNC drilling works. Drilling; Materials Suitable for Milling. CNC milling can be performed on a wide range of materials, making it highly versatile. Some common materials suitable for milling include: . Let’s take a look at how different factors can influence the decision between turning and milling: Part Design and Features: Consider the specific design .The CNC drilling parts are fabricated from wood, metals, hard plastics, or other rigid materials. Some of the common drill presses include Radial, Upright, and Bench. . regardless of whether you need simple or highly detailed machine parts. Our CNC milling and drilling machines produce parts of the same quality and standard, which means you .

CNC drilling technology creates precise holes and openings in these components, ensuring their functionality and reliability. #5. Plastic Manufacturing. Amazingly, the versatility of CNC drilling extends beyond plastic manufacturing. CNC drilling machines are frequently employed to shape plastic parts with intricate designs and varied applications. Understanding the fundamentals of CNC machining techniques, specifically milling, turning, and drilling, is essential for selecting the most appropriate process to create high-quality, precise parts.CNC Milling Machine Parts. There are various components of the general CNC milling machine. Let’s see them one by one. 01. Column . Milling machine are also used for drilling, boring, reaming tools for other operations. There are various types of milling machine are available. They are widely classified according to the number of needs and . It includes screens and buttons for controlling and programming the CNC machine. Spindle. The part of the machine that holds and rotates the drill bits or cutting tools. It has a gearing mechanism at the back end, which adjusts the speeds and torque during the drilling process. . What are the Main Differences Between CNC Milling and CNC .

In the CNC milling process, the milling machine leaves the remaining material on the workpiece. This residual material is called burr. They are usually formed along the bottom edge of the workpiece during milling or drilling. In addition, it is also common in softer materials with low hardness and strong plasticity. Cause

Repair Machining: Used to repair dimensional errors in machined holes to improve part accuracy and availability. 7. U Drill. U drills, also known as indexable insert drills, are a type of drill bit commonly used in CNC machining for drilling holes efficiently. The “U” in U drills typically refers to their U-shaped flutes, which are designed . 3. 1.2 Introduction Milling is a cutting operation with a geometrically specified cutting edge in which the tool makes the rotating main movement, and the feed as well as the infeed movement are generally made by the work part. .How accurate is CNC Drilling. CNC drilling can achieve tolerances as small as a thousandth of an inch. The machine, tooling, and programming primarily determine precision. Can CNC Drilling be used for large-scale production? .

schematic diagram of cnc machine

"Part 1 of our CNC milling operations and strategies guide includes face milling, side milling, slot milling, chamfering & beveling, copy milling, drilling, and more."CNC Milling is a widely used manufacturing process that produces CNC parts with precision and accuracy. It is a production process which involves the use of a 3D CAD design, tooling, and machine shop equipment such as heavy duty drill presses and CNC machines to produce a custom 3D CAD model.

Summary. Q. Write a CNC Part Program for the figure shown. For side milling, take speed 1200 rpm & feed 100 mm/min For drilling holes, take speed 1200rpm & feed 80mm/min For slot milling, take speed 1200rpm & feed 120mm/min Take hole diameter as 15mm Use absolute coordinate system.. Solution: Sequence of operation: 1 Set ref point, cordinate system, tool, give feed & .

CNC drilling is a suitable process for making holes in products and parts. Like any CNC machining process, it is accurate, precise, and has a low tolerance. As a result, it is an important process in product manufacturing that requires part assembly. . What is the difference between CNC milling and drilling? CNC hole drilling involves cutting . A batch of 100 aluminum parts might cost around 0 to drill, averaging per part. In contrast, drilling titanium, a much harder material, could elevate the cost to per part for the same batch size, due to increased tool wear and slower drilling speeds. . What is the difference between CNC Drilling and CNC Milling?Many spare parts can be replaced to allow an efficient use of your CNC industrial milling machine. MECANUMERIC provides you with parts such as clamping or lubrication systems, pins, spraying nozzles and drilling sprays for example.

CNC Drilling Shapes. Runsom offers custom CNC machining and drilling services at a rapid turnaround and competitive price for global customers. We focus on drilling and manufacturing parts with complex shapes in tight tolerance. Available shapes are square, round, flat oval, teardrop, D-shape, rectangle, and custom shapes. 4. A Wide Range of . The milling cutter is attached to a spindle which can operate on two or more axes. For example, a 2-axis milling machine can only cut horizontally and vertically. The most advanced CNC milling machines have five axes and incorporate rotational flexibility of the workpiece and cutting tool to allow for complex geometries. What is CNC Drilling? CNC drilling, using Computer Numerical Control technology, offers precise and efficient hole-making capabilities.The machines can be programmed to drill holes in various shapes and sizes, making them versatile tools in manufacturing. The process involves a rotating drill bit guided by the CNC machine to create holes in desired locations.

V1 offers worldwide clients affordable, rapid, high precision custom CNC Milling Services, variety of materials available to meet the needs of different industries! . Simple or complex CNC drilling parts designs are available in V1, as we provide best CNC machining services of low cost to meet your requirements. About Us. 16 Long Years Of . Alongside CNC drilling and turning, CNC milling forms the bedrock of the CNC machining process. However, it has a unique mechanism compared to the others. The process works by removing parts from a workpiece using a computer-controlled rotating cylindrical cutting tool that rotates and moves along multiple axes.

milling machine parts diagram

cnc router machine uk

cnc router machine bits

homemade cnc parts

$139.99

cnc milling and drilling part|cnc milling machine parts names