cnc machine coordinates Learn coordinate system fundamentals for any CNC machine, from the cartesian coordinate system to tool offsets. How to wire an electrical junction box. A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with easy to follow junction box wiring diagrams, including information on 20 and 30 amp junction boxes.

0 · what is g54 cnc code

1 · machine and work coordinate system

2 · coordinate systems in cnc machines

3 · cnc xyz axis chart

4 · cnc mill axis diagram

5 · cnc machine axis locations diagram

6 · cnc cartesian coordinate system

7 · cnc axis chart

If your house has visible wiring splices or if you need to add a new splice to extend a circuit, follow these simple steps to install a junction box.

Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space. Learn coordinate system fundamentals for any CNC machine, from the cartesian coordinate system to tool offsets.

Setting up the CNC lathe coordinate system is crucial in ensuring precise and efficient machining operations. It involves several key procedures to establish accurate spatial references and alignments within the machining environment.One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC .CNC Machinery refers to machines and devices that are controlled by using programmed commands which are encoded on to a storage medium, and NC refers to the automation of . Machine coordinates refer to the travel limits of the machine’s three axes. In some CNCs, those travel limits are designated with limit switches that are activated any time the router or spindle attempts to move beyond any of those .

The CNC machine will use the machine or default coordinate system to send the spindle to machine home. Operators do not set, reset, or choose machine coordinate systems. Machine coordinate systems are defined by the geometry .

Many CNC machines will have a way to toggle between polar and rectangular coordinates. For example, some machines use G16 enables polar coordinates. If G16 is enabled, X values are interpreted as the radius (distance) and Y .

Machine coordinate systems serve as a reference for the CNC machine to perform precise and accurate movements. They establish a three-dimensional framework that guides the machine . Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space. Learn coordinate system fundamentals for any CNC machine, from the cartesian coordinate system to tool offsets.

Setting up the CNC lathe coordinate system is crucial in ensuring precise and efficient machining operations. It involves several key procedures to establish accurate spatial references and alignments within the machining environment.One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC machine coordinate system, exploring its components, principles, and applications.

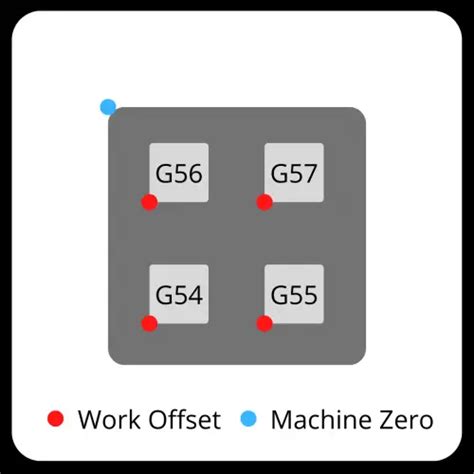

G54, G55, G56, G57, G58, and G59 (Usually referred to as “ G54-G59 “) are a group of CNC codes that specifies the “work offset” or the location of the workpiece on the machine’s table. They compensate for the workpiece’s position variations relative to the machine’s zero point.

CNC Machinery refers to machines and devices that are controlled by using programmed commands which are encoded on to a storage medium, and NC refers to the automation of machine tools that are operated by abstract commands programmed and encoded onto a storage medium. . Before putting in theses coordinates though, the machine operator needs . Machine coordinates refer to the travel limits of the machine’s three axes. In some CNCs, those travel limits are designated with limit switches that are activated any time the router or spindle attempts to move beyond any of those physical limits.

The CNC machine will use the machine or default coordinate system to send the spindle to machine home. Operators do not set, reset, or choose machine coordinate systems. Machine coordinate systems are defined by the geometry of the CNC machine.Many CNC machines will have a way to toggle between polar and rectangular coordinates. For example, some machines use G16 enables polar coordinates. If G16 is enabled, X values are interpreted as the radius (distance) and Y becomes the angle.

Machine coordinate systems serve as a reference for the CNC machine to perform precise and accurate movements. They establish a three-dimensional framework that guides the machine in executing the desired toolpaths. Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space.

what is g54 cnc code

Learn coordinate system fundamentals for any CNC machine, from the cartesian coordinate system to tool offsets.Setting up the CNC lathe coordinate system is crucial in ensuring precise and efficient machining operations. It involves several key procedures to establish accurate spatial references and alignments within the machining environment.One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC machine coordinate system, exploring its components, principles, and applications.G54, G55, G56, G57, G58, and G59 (Usually referred to as “ G54-G59 “) are a group of CNC codes that specifies the “work offset” or the location of the workpiece on the machine’s table. They compensate for the workpiece’s position variations relative to the machine’s zero point.

CNC Machinery refers to machines and devices that are controlled by using programmed commands which are encoded on to a storage medium, and NC refers to the automation of machine tools that are operated by abstract commands programmed and encoded onto a storage medium. . Before putting in theses coordinates though, the machine operator needs . Machine coordinates refer to the travel limits of the machine’s three axes. In some CNCs, those travel limits are designated with limit switches that are activated any time the router or spindle attempts to move beyond any of those physical limits.The CNC machine will use the machine or default coordinate system to send the spindle to machine home. Operators do not set, reset, or choose machine coordinate systems. Machine coordinate systems are defined by the geometry of the CNC machine.Many CNC machines will have a way to toggle between polar and rectangular coordinates. For example, some machines use G16 enables polar coordinates. If G16 is enabled, X values are interpreted as the radius (distance) and Y becomes the angle.

sheet metal fabrication company in chennai

sheet metal fabrication ce

An electrical junction box is a safety box used to cover wires that have been joined in a single electrical unit. An electrical junction box can either be made of metal or plastic. To save on costs, plastic junction boxes offer a .

cnc machine coordinates|cnc cartesian coordinate system