electrical metallic tubing in house studs The rule is that the studs in any exterior or load-bearing wall may be notched, but no deeper than 25% of the width of the stud, or a hole no . Provide protection for water heaters installed in outdoor locations; Water heater enclosures are constructed of galvanized steel; Anchor points at the rear of the enclosure allow for optional attachment to the adjacent building structure; Easy assembly with basic tools

0 · working with metal stud wiring

1 · notching studs for walls

2 · notching studs for electrical installation

3 · metal studs for walls

4 · metal stud wiring instructions

5 · metal stud wiring for wall

6 · metal stud wiring diagram

7 · framing studs electrical

Fabricating with Pride in Washington State Since 1976. All of our custom welding and welding technicians are factory certified with years of real-world experience under their belts. Using MIG, TIG and STICK techniques, our team is capable of welding aluminum, mild steel, bronze, brass, iron, copper, cast, stainless steel and plastic for any .

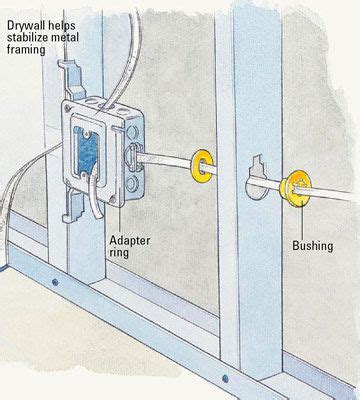

Steel studs come with pre-cut keyholes designated for threading electrical wires. Determine the route you want your wires to go. Where the cable runs through a stud, snap a protective bushing into place. These come in two pieces that press together.EMT (electric metallic tube, also called thin-wall) is strong enough for most interior .

The rule is that the studs in any exterior or load-bearing wall may be notched, but no deeper than 25% of the width of the stud, or a hole no . Residential buildings are an acceptable place for NM run in steel studs as long as plastic bushings are installed properly , and the building type meets the requirements set forth . In this guide, we’ll explore the essential tools, techniques, and safety considerations for drilling into studs for electrical wiring. In the video, master electrician Heath . Metal stud wiring offers durability, fire resistance, and pest resistance, making it a reliable and long-lasting choice for electrical installations. It provides flexibility in design, ease of installation, and cost-effectiveness .

Steel studs come with pre-cut keyholes designated for threading electrical wires. Determine the route you want your wires to go. Where the cable runs through a stud, snap a protective bushing into place. These come in two pieces that press together.

Choose a power source like a wall receptacle and run electrical metallic tubing (EMT) right on the wall to your new basement or garage workbench. EMT is often called 'thinwall conduit,' Thinwall conduit does not need to be threaded like rigid metal conduit (RMC).

Learn if exposed wire is allowed, its dangers, and workarounds like THHN wire for exposed sheathed cables in your home. The National Electrical Code, the basis for all local building codes, has specific regulations for installing electrical wires so that they are protected from damage to avoid fire, shocks, and trips or surges. The rule is that the studs in any exterior or load-bearing wall may be notched, but no deeper than 25% of the width of the stud, or a hole no bigger than 40% of the width of the stud may be bored in it (you could pass the conduit or cable through the stud). Residential buildings are an acceptable place for NM run in steel studs as long as plastic bushings are installed properly , and the building type meets the requirements set forth in the code book for where NM cable can be installed.

In this guide, we’ll explore the essential tools, techniques, and safety considerations for drilling into studs for electrical wiring. In the video, master electrician Heath Eastman demonstrates these techniques, sharing trade secrets that make the process both accurate and code-compliant. Metal stud wiring offers durability, fire resistance, and pest resistance, making it a reliable and long-lasting choice for electrical installations. It provides flexibility in design, ease of installation, and cost-effectiveness compared to traditional wooden studs.

To successfully install electrical boxes on metal studs, keep these tips in mind: Use a level to make sure the boxes are level before securing them. If necessary, pre-drill holes in the metal studs to prevent splitting or deformation, especially for older or thinner stud materials.

Electrical Metallic Tubing (EMT) is the lightweight champion of electrical conduits, offering durability without the bulk. Made from galvanized steel or aluminum, EMT stands out for its ease of manipulation (cutting, bending, assembling) making it a popular choice among electricians for various installations. EMT (electric metallic tube, also called thin-wall) is strong enough for most interior home installations. Outdoors, use IMC (intermediate metal conduit) or PVC conduit. Codes have detailed rules regarding conduit size, but generally, 1/2-inch conduit is large enough for five or fewer wires; 3/4-inch conduit is used for more than five wires .

Steel studs come with pre-cut keyholes designated for threading electrical wires. Determine the route you want your wires to go. Where the cable runs through a stud, snap a protective bushing into place. These come in two pieces that press together. Choose a power source like a wall receptacle and run electrical metallic tubing (EMT) right on the wall to your new basement or garage workbench. EMT is often called 'thinwall conduit,' Thinwall conduit does not need to be threaded like rigid metal conduit (RMC).

Learn if exposed wire is allowed, its dangers, and workarounds like THHN wire for exposed sheathed cables in your home. The National Electrical Code, the basis for all local building codes, has specific regulations for installing electrical wires so that they are protected from damage to avoid fire, shocks, and trips or surges. The rule is that the studs in any exterior or load-bearing wall may be notched, but no deeper than 25% of the width of the stud, or a hole no bigger than 40% of the width of the stud may be bored in it (you could pass the conduit or cable through the stud).

working with metal stud wiring

Residential buildings are an acceptable place for NM run in steel studs as long as plastic bushings are installed properly , and the building type meets the requirements set forth in the code book for where NM cable can be installed. In this guide, we’ll explore the essential tools, techniques, and safety considerations for drilling into studs for electrical wiring. In the video, master electrician Heath Eastman demonstrates these techniques, sharing trade secrets that make the process both accurate and code-compliant. Metal stud wiring offers durability, fire resistance, and pest resistance, making it a reliable and long-lasting choice for electrical installations. It provides flexibility in design, ease of installation, and cost-effectiveness compared to traditional wooden studs. To successfully install electrical boxes on metal studs, keep these tips in mind: Use a level to make sure the boxes are level before securing them. If necessary, pre-drill holes in the metal studs to prevent splitting or deformation, especially for older or thinner stud materials.

Electrical Metallic Tubing (EMT) is the lightweight champion of electrical conduits, offering durability without the bulk. Made from galvanized steel or aluminum, EMT stands out for its ease of manipulation (cutting, bending, assembling) making it a popular choice among electricians for various installations.

metal wallplate for house bell

metal vs plastic electrical box

The galvanized steel scrubbing surface and natural pine wooden frame of Behrens small washboard is perfect for removing stains or adding a vintage flair.

electrical metallic tubing in house studs|metal stud wiring for wall