parts of a cnc lathe The faceplate is fixed to the lathe spindle and can be job mounted to perform the turning operation. Center Center is a part of lathe machine which is used to support long jobs in between headstock and tailstock to carry out a lathe operation. A center that fits into the headstock spindle and rotates with the workpiece is called a live center. 16 . A distribution box works by receiving power from a main source and distributing it to various circuits. It uses circuit breakers or fuses to protect each circuit from overloads. What Are The Types Of Distribution Boxes? There are several types of distribution boxes, including residential, commercial, and industrial.

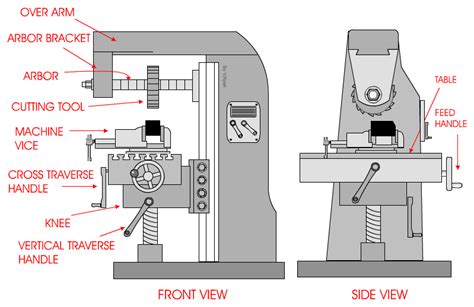

0 · milling machine block diagram

1 · components of cnc milling machine

2 · cnc milling machine diagram

3 · cnc machining process flow chart

4 · cnc machine schematic diagram

5 · cnc lathe machine diagram

6 · cnc lathe diagram

7 · block diagram of cnc machine

You want the screws to go into the mounting plate behind the top of the box, and some way past the mounting plate, but not contact the top of the mounting bar. The "locking means" would be a lock washer which impedes loosening of the screw from vibration. Some screws have a captive lock washer, but an added lock washer would do. –

milling machine block diagram

An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time.Here, we will explore the main components that make up a CNC lathe machine. We will take a closer look at the bed and headstock, tailstock and carriage, chuck and spindle, tool turret and .Welcome to our in-depth exploration of CNC lathe machine parts and functions. In this comprehensive guide, we will take you on a journey through the inner workings of a CNC lathe machine, providing detailed insights into the various components that make it function seamlessly. Whether you are a CNC enthusiast, a machining professional, or .

It is suitable for turning processing of general rotating parts. This CNC lathe can control two axes at the same time, i.e. X-axis and Z-axis. Rotary machining center: C-axis and power head are added to the general CNC lathe. More .The faceplate is fixed to the lathe spindle and can be job mounted to perform the turning operation. Center Center is a part of lathe machine which is used to support long jobs in between headstock and tailstock to carry out a lathe operation. A center that fits into the headstock spindle and rotates with the workpiece is called a live center. 16 .

metal sheet uses

The turret provides the ability to change the cutting tools as required. The number and size of the cutting tools will determine the turret’s size. The CNC lathe tool turret rotates with the CNC program commands. And this rotation depends on the CNC lathe machine. #20. Apron. The apron is part of the carriage that houses the control mechanisms. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of machine.

Due to the fact that the workpieces are secured to the headstock, it is one of the key parts of CNC lathe machines. The primary axle of the CNC lathe is driven by motors. The Tailstock. When a CNC machine is used to conduct tasks like noodling, threading, and turning, this lathe gives the workpiece more grip. On the workpiece’s end surfaces . Valiant, what I have done, is turn a headed bushing in the lathe to say 1/2" dia, then ream it out to your part size. Don't part it off and take it over to the mill and slit it to the center lengthwise, with a .04 thick saw to make a collet then saw it off (just like a toolholder bushing). Turn your chuck pressure down and throw it in the cnc . CNC LATHE (CNC LATHE (MTAB)MTAB) Program build-up for CNC Lathe using FANUCProgram build-up for CNC Lathe using FANUC System.System. CNC Program can be divided into three parts.CNC Program can be divided into three parts. 1. Start-up Program1. Start-up Program 2. Profile Program2. Profile Program 3. End of the Program3. End of the Program

CNC lathe is very efficient in the precision manufacturing of fine details parts like thread, cylinder etc., all rotationally symmetrical components of the workpiece. They do this by creating more accurate automobile components such as brake discs and crankshaft bearings on their CNC machines.A CNC lathe machinist may use a lathe CNC machine for sale. If you are a business owner,plant manager, or supervisor responsible for purchasing a used CNC lathe machine for sale, it is essential to understand them. . By partnering with Richonn, you can expect to receive high-quality CNC machining parts and exceptional service. Parts of the CNC Lathe Machine and their functions Let’s look at the major components of a Headstock Different types of CNC Lathe Machines Like the Flat Bed CNC Lathe Machine uses Headstock, which is an important component of CNC Machine that drives the motor and powers the spindle. The front component of a CNC turning machine is made up of .About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Best Upgrade for CNC Lathe Machine Parts. The best upgrade for CNC lathe machine parts varies depending on user needs. A range of possible improvements can be considered depending on the quality of the lathe machine parts. Examples are: Improved Controller: Better controller hardware can improve capabilities and program editing. Non .

11. • By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as permitting diagnostics and quality control functions during the actual machining. • All CNC machining begins with a part program, which is a sequential instructions or coded . CNC lathe is a powerful machine tool that is used to create high-quality shape materials by removing excess materials from the workpiece. However, you should get the best CNC Lathe types and parts to get the best . CNC lathe machine parts play an indispensable role in modern manufacturing, pushing the boundaries of precision and intricacy in products across various industries. At the heart of this manufacturing revolution is the .Bed: The bed is a fundamental parts of cnc lathe, providing a stable base for the entire machine. It supports the headstock, carriage, and tailstock, ensuring that all components are aligned and secure during operation. 2. Headstock: The headstock is a key component of a CNC lathe, housing the spindle. This spindle is a central part of the .

These are complex machines that can manufacture precision parts. A CNC lathe machine is a computer-controlled tool that rotates a workpiece on a spindle to perform many CNC operations. Given their complexity, CNC lathe machines have multiple parts, each serving a specific function so the machine can operate smoothly and efficiently. . Common types of CNC machines include; CNC lathe machines, CNC milling machines, CNC routers, 3D printers, and Laser and Plasma Cutters. In this article, I’ll focus on the basics of CNC milling machines. Keep reading to learn all you need to know – from the parts of a CNC mill to how CNC milling works and everything in between. Tormach 15L Slant-PRO™ CNC Lathe | Tormach Inc. providers of personal small CNC machines, CNC tooling, and many more CNC items. It does well if you are running a few parts and don't mind fairly slow speed. I've turned 303SS and 304SS on mine with no trouble on lots of 50 or 100 small parts.

Understanding CNC Lathe Machine Parts. A centre lathe machine consists of several essential parts, each playing a crucial role in its operation. The main components include the spindle, chuck, tailstock, carriage, and bed. The spindle rotates the workpiece being machined while the chuck securely holds the workpiece in place.A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

components of cnc milling machine

cnc milling machine diagram

Learn with us and Become Professional CNC Coordinate system Explained, Absolute & Incrementalhttps://youtu.be/PNSvawA0BoEMastercam Free .

Vertical beam: An essential CNC lathe machine part that minimizes swarf accumulation, unlike manual lathes with beds. Other important CNC lathe machine parts include: Chuck : The mechanical device used to securely hold workpieces, which is attached at the lathe’s spindle nose with screws; the two types are either 3-jaw or 4-jaw chucks, also . With a CNC lathe machine, parts for other equipment can be made more efficiently, along with a vast array of other items. Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding and rotating a workpiece around a cutting tool. With three-axis CNC lathes, operators can perform more intricate operations, such as contouring, grooving, and facing at different angles. For even more advanced operations and greater part complexity, some CNC lathes utilize a fourth axis, known as the B-axis. The B-axis provides rotational movement and allows for off-axis machining. CNC lathe machine produces the most accurate products as compared to the other type of the lathe machine. In CNC Lathe machine program are being fed to the computer system which controls the overall working of the lathe. CNC lathe machines are used for large scale Production. Semi- skilled workers are required for the operation of this machine.

metal sheet stamped parts

On normal electrical boxes, screws are usually 6-32. this being a bit light for a fan, also expect 8-32 or 10-32. Ground screws are 10-32. It's not a coincidence that they are -32, given the thickness of standard metal junction boxes, that is the minimum number of threads to properly engage. Never use sheetmetal screws.

parts of a cnc lathe|milling machine block diagram