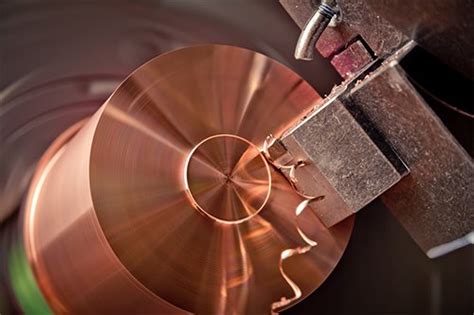

cnc cutting complex copper parts AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in applications that require .

My experience is that single-gang, double-gang, etc. mud rings are usually intended for receptacles & switches and usually come tapped for 6/32 screws. There are .

0 · types of copper for cnc

1 · copper machining

2 · copper for cnc processing

3 · copper for cnc machining

4 · copper cutting angle

5 · copper cnc machining guide

6 · cnc machining copper types

7 · cnc copper manufacturing process

Here are the steps to be followed to calculate sheet metal flat length: Step-1: .

Skilled professionals utilize top-notch CNC milling and turning techniques, including CNC copper machining, to machine copper parts with expertise and precision. Advanced CNC . AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in .

XTJ offers a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher . Skilled professionals utilize top-notch CNC milling and turning techniques, including CNC copper machining, to machine copper parts with expertise and precision. Advanced CNC mills and turning centers are operated to create parts with simple to complex geometries, maintaining tight tolerances.

We offer a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics. AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in applications that require .XTJ offers a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.CNC machining of copper utilizes advanced technology to sculpt parts with unmatched precision, leveraging copper's excellent thermal and electrical conductivity. This process, suitable for both prototyping and mass production, employs 3-axis and 5-axis milling to create components with complex geometries and high-quality finishes.

Get custom CNC-machined copper parts with precision and fast delivery in as little as 3 days. From prototypes to mass production, 3ERP offers high-quality copper machining solutions.

Sibai efficiently produces a wide range of complex custom copper parts to meet the needs of orders of varying sizes. Sibai provides strict quality control in the whole production process to ensure cnc copper parts meet the highest standards, from material to finishing, to packing.

CNC copper machining technology, as a high-precision metal machining method, uses the characteristics of different copper materials to implement milling, drilling, turning and other processes through CNC machine tools to accurately manufacture complex and .With the appropriate cutting tools, coolant, and machining parameters, high-quality copper parts can be produced using CNC machining. What is the best tooling for machining copper? The best tooling for machining copper depends on the specific application and machining technique used.From medical devices to aerospace components, precision-machined copper parts are in high demand. Compared to other metals, copper offers its own challenges, so deep manufacturing expertise and experience is required to work with it. At RPM Inc., our seasoned experts and cutting-edge facility ensure top-quality copper CNC machining. Copper CNC . Skilled professionals utilize top-notch CNC milling and turning techniques, including CNC copper machining, to machine copper parts with expertise and precision. Advanced CNC mills and turning centers are operated to create parts with simple to complex geometries, maintaining tight tolerances.

We offer a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics. AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in applications that require .XTJ offers a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.CNC machining of copper utilizes advanced technology to sculpt parts with unmatched precision, leveraging copper's excellent thermal and electrical conductivity. This process, suitable for both prototyping and mass production, employs 3-axis and 5-axis milling to create components with complex geometries and high-quality finishes.

Get custom CNC-machined copper parts with precision and fast delivery in as little as 3 days. From prototypes to mass production, 3ERP offers high-quality copper machining solutions.Sibai efficiently produces a wide range of complex custom copper parts to meet the needs of orders of varying sizes. Sibai provides strict quality control in the whole production process to ensure cnc copper parts meet the highest standards, from material to finishing, to packing.CNC copper machining technology, as a high-precision metal machining method, uses the characteristics of different copper materials to implement milling, drilling, turning and other processes through CNC machine tools to accurately manufacture complex and .

With the appropriate cutting tools, coolant, and machining parameters, high-quality copper parts can be produced using CNC machining. What is the best tooling for machining copper? The best tooling for machining copper depends on the specific application and machining technique used.

types of copper for cnc

copper machining

copper for cnc processing

copper for cnc machining

copper cutting angle

Sheet metalworking, also known as Sheet metal forming and sheet metal fabrication, is a manufacturing process of cutting and forming relatively thin metal sheets, strips, and coils to create desired shape sheet metal parts. Because manufacturers typically perform these operations on presses with a set of dies, the terms pressworking or press .

cnc cutting complex copper parts|copper cutting angle