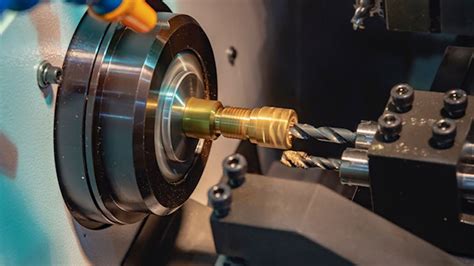

cnc machining brass part Machinists commonly refer to this alloy as free machining brass. It is the most common brass grade used in machining. It is renowned for its high machinability and tensile strength. Its high machinability is attributed to its lead content which makes up about 3% of its constituents. Machinists use it for machining . See more CNC milling machines are used to create complex and detailed parts, especially when working with metals, plastics, and wood. They are essential in the production of molds, dies, and prototypes. Manufacturing components for automobiles and airplanes. Creating precision molds and dies. Producing custom parts for electronic products. 2.

0 · machinability of brass

1 · is brass easy to cut

2 · copper and brass machine shops

3 · cnc machine for brass parts

4 · cnc machine for brass

5 · cnc brass parts

6 · brass machinability chart

7 · brass against the machine coplot

CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, lathes, and grinders. This process is known for its high precision and versatility in creating a wide range of materials, including metal, plastic, wood, foam, and .

machinability of brass

public image ltd metal box zip

Machinists commonly refer to this alloy as free machining brass. It is the most common brass grade used in machining. It is renowned for its high machinability and tensile strength. Its high machinability is attributed to its lead content which makes up about 3% of its constituents. Machinists use it for machining . See moreMachinists refer to this grade as the red brass or Nordic brass. It also has moderate strength and good anti-rust properties. The C230 is popular for its season-breaking and . See moreMachinists refer to this alloy as commercial bronze. Despite the name, its constituent still makes it a brass alloy due to its higher copper content. It has a good machinability rating, . See moreDiscover the benefits of precision brass CNC machining for custom brass parts. Get insights on brass types, applications, and more. Order your brass parts with confidence.

Brass stands out for its strength, machinability, and corrosion resistance, making it one of the most versatile materials for CNC machining. Excellent machinability: Brass is known for being incredibly easy to machine, making it a favorite for .

Brass CNC machining is a key innovation in manufacturing, blending material resilience with technological precision. It ensures versatile, high-quality components, marking a significant advancement in production .Brass C360 remains the industry standard for general machining and high volume production. The excellent machinability characteristic of C360 permits full utilization of a screw machine’s capabilities.Brass, a mix of copper and zinc, is highly valued as raw material for CNC machining in many industries. Its toughness, low friction, and resistance to wear make it perfect for CNC machined brass parts.Brass is widely used for making . The process of CNC machining a part often varies depending on the metal or metal alloy you are working with. Brass is no different in that manner, however, there are some key differences that separate it from other possible selections. Overall brass is considered highly machinable, but that does not mean it is a great choice for all applications.

We offer a complete CNC machining service for brass parts and can produce complex Brass parts in Brass C360. Brass parts are great for applications that require high strength, corrosion resistance, a low friction coefficient, electrical .

Specialized in custom-made Brass turned parts & machined parts. Precision brass machining components according to customers' specifications. Boly Metal. Address Units 705-706, 7 . flange and other machine parts by lathe and CNC. Brass C4926. A low leaded free cutting brass which conform RoHs and Reach environment regulations. Widely used on .It means that we can always fulfill orders and produce highly complex brass parts. Our brass CNC machining shop can produce custom brass parts using CNC lathes and 3- and 5-axis CNC milling machines. Brass is very suitable for different industries such as plumbing, electrical and medical. It has excellent durability.3ERP provides comprehensive CNC brass machining services that produce parts and components with exceptional accuracy and precision from different brass alloys. Brass alloy is an ideal choice for CNC machining due to its malleability, high corrosion resistance, and .

is brass easy to cut

Maximum Savings on Custom Brass Machining Parts. Delivery To Suit Your Schedule. RFQ. ISO:9001:2008 Certified. . brass cnc machining parts. 1 2 > Product Categories. Milling parts; Turning parts; Machining parts. alumium parts; brass parts; stainless steel parts; titanium parts; magnesium parts;W.H. Bagshaw Company offers custom-made precision CNC brass parts and components for any application. . Free Machining Brass: Also known as C36000, alloy 360, or free cutting brass, free machining brass consists of approximately 60%-63% copper, 33%–37% zinc, 2.5%–3% lead, and 0.35% iron. It is one of the most versatile and commonly used .Turned brass parts and components are durable, cost-effective, and can even make fittings more tightly sealed. In addition, brass machining and turning parts have high heat resistance and corrosion resistance! SANS has more than 10 years of experience in precision parts machining. We can provide customized machining service according to your .Our 5-axis CNC machine shops have the capability of creating machined brass parts and components that are durable and cost-efficient, particularly creating tighter seals for fittings commonly applied in precision engineering for manufacturing cylinder parts or electronic hardware. The tight tolerance and complex geometry of brass parts would be .

The Art and Precision of CNC Machining Brass Parts CNC (Computer Numerical Control) machining has revolutionized the manufacturing landscape, particularly when it comes to producing high-quality brass parts. With advancements in technology, the ability to create highly detailed and precise components has drastically improved. This article aims to explore the.

Discover High-Quality Brass CNC Machining Solutions at Sheldon Precision . At Sheldon Precision, we pride ourselves on achieving exact specifications and the highest quality in every brass-turned part. Our expertise as a brass turned parts manufacturer extends to a wide range of industries, and we offer brass CNC-turned parts that are . If you were to do a brass CNC part in 200,000 units or something as low as 500 units, the fact of being able to cut this material at a lower power meaning being able to machine it slightly faster. That is exactly why certain people in the mass production industry do use brass for certain specific applications where it will perform much better .

eMachineShop has machined brass parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. . CNC Turning. CNC Lathes feed cutting tools into rotating material. Turning is mainly used to produce precise, cylindrical parts. EDM. Die-Sink and Wire EDM machines create .Brass is a costly material, so optimization of its use is recommended. Design for manufacturing (DFM): Even though brass is easy to machine, take care to design parts that follow the applicable DFM principles.In addition to this, designing .CNC Machining Materials for Copper Parts. The excellent thermal and electrical conductivity of 101 and 110 copper alloys makes them a natural choice for bus bars, wire connectors, and other electrical applications. 101 copper (also .Our CNC milling for brass parts offers precise, accurate cutting and shaping of brass components with high-precision performance. The milling process is fast and efficient, resulting in superior-quality parts with a high degree of .

Dongguan Yaside Precision Machinery and Equipment Co., Ltd.: It is mainly engaged in the processing of large and precision industrial equipment parts, and manufactures some precise, complex, high-precision and various parts. With large-scale, high-precision high-end equipment, advanced testing equipment, and professional quality inspection personnel, it can ensure that .210 230 260 270 360 C37700 brass CNC machining services, ISO9001 certified quality control, precision CNC turning and milling of custom brass parts. . Therefore, it is important to set the correct feed rate before machining brass parts, as it affects the quality, service life and surface finish of the brass part. .

we used to run 10k pc lots of brass parts and never had to change tools and made only the slightest adjustments to offsets. run the rpm as high as is feasible (vibration will be an issue if running from bar) and feed it hard. not running coolant has 1 benefit, cleaner chips for the scrap guy. . CNC Machining. ABOUT PRACTICAL MACHINIST. In brass CNC machining, a design is first created using computer-aided design (CAD) software. The design is then converted into numerical code or G-code, which the CNC machine can understand. . The addition of lead results in improved machinability, which makes it ideal for producing intricate and complex parts through machining processes .Brass CNC machining is a procedure to cut, shape and form the brass material into final product with aid of computer numerical control (CNC) machines. These are very precisionful & accurate machines which make possible the complex part manufacturing at accuracy levels.Rally's CNC brass machining services stand out in the industry for their superior accuracy, customizability, and experience. Featuring state-of-the-art CNC technology, we are able to produce brass parts that are extremely accurate and meet the tightest tolerances.

LJZ is one of the brass machining suppliers specialized in providing you high-quality brass and copper CNC machining service. Common copper can be 101,110 and pure copper. . Our commonly used surface treatments for CNC China brass machining parts and copper machined parts are passivation and electroplating.Introduction. Brass is a top material for CNC machining, a subtractive manufacturing process using computer controls.It involves cutting away material from a solid brass workpiece following a digital design. This method allows creating precise, intricate components with tight tolerances and complex shapes.CNC Machining Brass Parts. CNC Machining Brass has superior mechanical properties, good plasticity and processability, and can meet various processing needs. Making brass parts. Brass Description. Brass is an alloy mainly composed of copper and zinc, which has good toughness and plasticity, wear resistance, corrosion resistance, and machinability.Brass CNC Machining Applications. Companies choose brass to manufacture a broad range of products and components across many industries, including plumbing, automotive, filtration and more. At DW Products, our engineers and machine operators leverage decades of experience designing, testing and manufacturing the most durable, highest-performing brass components.

What is a Bend Relief? A bend relief is nothing more than two small incisions cut into a piece of sheet metal to free the metal between the two. It separates the material you want to be able to fold from the rest of the part. You only need it when there is material on either side of a .

cnc machining brass part|copper and brass machine shops