convert step file to sheet metal solidworks The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Select Use gauge table. Drill bits are the cutting tools of drilling machines. They can be made in any size to order, but standards organizations have defined sets of sizes that are produced routinely by drill bit manufacturers and stocked by distributors. In the U.S., fractional inch and gauge drill bit sizes are in common use. In nearly all other countries, metric drill bit sizes are most common, and all others are anachronisms or are reserv.

0 · solid work to sheet metal conversion

1 · solid work to sheet metal

2 · rip sketch

3 · rip SolidWorks

4 · convert solid to sheet metal

5 · convert metal to sheet metal

6 · convert imported metal to SolidWorks

7 · SolidWorks convert sheet metal to metal

To properly lubricate bronze bushings, the interior of the bushing needs to be accessed, requiring removal of any shafts or accessories the bushing is designed to hold. If the bushing is being removed, a slide hammer is needed to loosen the bushing, and an appropriately sized bushing installer is required to reinstall the bushing.

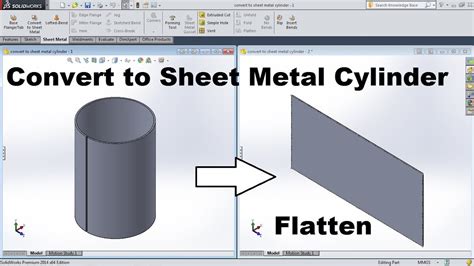

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Select Use gauge table.To convert an imported sheet metal part: Import the part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal .

Import the STEP file and use the Convert to Sheetmetal tool to select the outer faces. You can then specify the material thickness and default bend radius for your parts. Be sure to check the . Having issues converting STEP and IGES files to sheet metal? Watch this video for tips on how to convert them!Converting an Imported Part to a Sheet Metal Part. You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet .

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. When using the Convert to .

Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or .

Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. . Transform geometry into Sheet Metal. The next step is to transform the geometry into a real sheet metal part so it can be flatten. To achieve this, we will utilize the “Insert Bends” command from the Sheet Metal command .

solid work to sheet metal conversion

cnc laser cut sheet metal manufacturer

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Select Use gauge table.To convert an imported sheet metal part: Import the part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal .

Import the STEP file and use the Convert to Sheetmetal tool to select the outer faces. You can then specify the material thickness and default bend radius for your parts. Be sure to check the "Delete original body" option so you don't end up with two parts in your model.Having issues converting STEP and IGES files to sheet metal? Watch this video for tips on how to convert them!Converting an Imported Part to a Sheet Metal Part. You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet Metal. When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body .

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. When using the Convert to Sheet Metal tool, you can keep the solid body to use with multiple Convert to Sheet Metal features.

cnc injection molding manufacturers

Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. Step 3: Sheet metal gauge table. Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. Method 1: Use the Convert to Sheet Metal tool; Method 2: Insert Rips and Bends into the part Transform geometry into Sheet Metal. The next step is to transform the geometry into a real sheet metal part so it can be flatten. To achieve this, we will utilize the “Insert Bends” command from the Sheet Metal command manager tab. Notice that there is also “Convert to Sheet Metal” command.The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Select Use gauge table.

To convert an imported sheet metal part: Import the part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Import the STEP file and use the Convert to Sheetmetal tool to select the outer faces. You can then specify the material thickness and default bend radius for your parts. Be sure to check the "Delete original body" option so you don't end up with two parts in your model.

Having issues converting STEP and IGES files to sheet metal? Watch this video for tips on how to convert them!Converting an Imported Part to a Sheet Metal Part. You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet Metal. When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body .This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.

Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. When using the Convert to Sheet Metal tool, you can keep the solid body to use with multiple Convert to Sheet Metal features. Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. Step 3: Sheet metal gauge table. Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. Method 1: Use the Convert to Sheet Metal tool; Method 2: Insert Rips and Bends into the part

solid work to sheet metal

cnc hydraulics spare part

The first step in the installation process is to figure out how high you want your TV to be. We recommend centering the TV at your eye level to . See more

convert step file to sheet metal solidworks|solid work to sheet metal conversion