cnc machine offset process Taking offsets correctly is essential to achieve the desired precision in CNC machining. Accurate offsets eliminate errors caused by variations in tools, fixtures, and workpiece setup. By . The CB140PT is a conduit box for turret camera. The bracket should be installed on a flat wall. The wall must be capable of supporting a minimum of three times the total weight of the camera and mount. The maximum load capacity of the bracket is 9.92 lbs. Features: Aluminum Alloy Material with Surface Spray Treatment

0 · what is wear offset

1 · what is tool length offset

2 · offset turning on cnc lathe

3 · offset meaning in cnc programming

4 · offset in cnc lathe

5 · geometry vs wear offsets

6 · cnc work offsets

7 · cnc tool offsets explained

Turning Right at a Box Junction. When it comes to handling yellow box junctions while turning right, there’s a specific set of rules to follow. You’re allowed to stop in the box if you’re turning right, but it’s crucial to ensure that your exit road is clear.

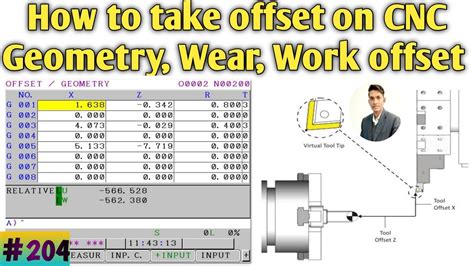

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.

Taking offsets correctly is essential to achieve the desired precision in CNC machining. Accurate offsets eliminate errors caused by variations in tools, fixtures, and workpiece setup. By .

CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best .In this section, we'll walk you through a detailed step-by-step process of setting work offsets in a CNC machine. We'll cover key elements such as zeroing the machine, entering offsets, and . Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine. Delve into the world of CNC offsets and how they can prevent errors in your machining operations. From defining offsets to exploring real-world examples, gain valuable insights on how to avoid expensive mistakes in .

what is wear offset

Learn what tool length offsets are, why they’re important, where to find them on your machine, and how to set them. The Machining Fundamentals series will help you brush up on your CAM knowledge, whether you work in a .

There are two types of offsets required for work. Tool offset is nothing but the required values and measures we use to style a tool and shift the position of the tool. If we all know the precise tool offsets, we will find the . Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.

Taking offsets correctly is essential to achieve the desired precision in CNC machining. Accurate offsets eliminate errors caused by variations in tools, fixtures, and workpiece setup. By understanding the importance of offsets, operators can minimize material waste, reduce downtime, and produce high-quality parts consistently. Steps to Take .In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by.

what is tool length offset

CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best practices for offset management, machinists can achieve higher levels of .

In this section, we'll walk you through a detailed step-by-step process of setting work offsets in a CNC machine. We'll cover key elements such as zeroing the machine, entering offsets, and verifying their accuracy. Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine. Delve into the world of CNC offsets and how they can prevent errors in your machining operations. From defining offsets to exploring real-world examples, gain valuable insights on how to avoid expensive mistakes in manufacturing. Learn what tool length offsets are, why they’re important, where to find them on your machine, and how to set them. The Machining Fundamentals series will help you brush up on your CAM knowledge, whether you work in a machine shop or new to machining.

offset turning on cnc lathe

There are two types of offsets required for work. Tool offset is nothing but the required values and measures we use to style a tool and shift the position of the tool. If we all know the precise tool offsets, we will find the precise machining start line.With work holding and work offsets mastered, you are now poised to move on to the next critical step - setting up tools. This topic will be explored in next week’s video. Dive into work holding and offsets on your Tormach CNC mill. We will guide you through vise setup, strap clamps, and more for secure machining.

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.Taking offsets correctly is essential to achieve the desired precision in CNC machining. Accurate offsets eliminate errors caused by variations in tools, fixtures, and workpiece setup. By understanding the importance of offsets, operators can minimize material waste, reduce downtime, and produce high-quality parts consistently. Steps to Take .

In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by.

CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best practices for offset management, machinists can achieve higher levels of .In this section, we'll walk you through a detailed step-by-step process of setting work offsets in a CNC machine. We'll cover key elements such as zeroing the machine, entering offsets, and verifying their accuracy. Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine. Delve into the world of CNC offsets and how they can prevent errors in your machining operations. From defining offsets to exploring real-world examples, gain valuable insights on how to avoid expensive mistakes in manufacturing.

Learn what tool length offsets are, why they’re important, where to find them on your machine, and how to set them. The Machining Fundamentals series will help you brush up on your CAM knowledge, whether you work in a machine shop or new to machining. There are two types of offsets required for work. Tool offset is nothing but the required values and measures we use to style a tool and shift the position of the tool. If we all know the precise tool offsets, we will find the precise machining start line.

offset meaning in cnc programming

offset in cnc lathe

geometry vs wear offsets

TwinBox PV-junction box set Author: Stäubli Electrical Connectors AG/Switzerland Subject: Designed for fully automated assembly. Compact design due to integration of the MC4 .

cnc machine offset process|cnc work offsets