electrical box grouding wire attachment Installing a ground wire to your electrical service panel can be done easily with a few hand tools. The codes of some localities differ from NEC (National Electric Code) .

A "Gem" box is another word for a sectional metal device box, or most commonly referred to as an old work box. You know, the kind you install with "madison straps." They were also commonly used for new work for many decades until the advent of the far superior Carlon non-metallic boxes.:thumbup:Like standard rectangular boxes, gangable electrical boxes hold household switches and electrical outlets. Still, they are oversized so that two, three, or four devices can be mounted side-by-side. Gangable electrical boxes are often made of durable galvanized steel.

0 · metal junction box wire

1 · how to ground wire boxes

2 · how to ground electrical boxes

3 · grounding electrical wires in fixtures

4 · grounding electrical wire in box

5 · ground wire to electrical panel

6 · electrical wire grounding guide

7 · electrical box installation

What is an electrical junction box used for? An electrical junction box is used for several purposes, including: Containing and protecting electrical connections, such as wire splices and wire terminations. Preventing contact with live wires, which reduces the risk of electrical shocks and fires.

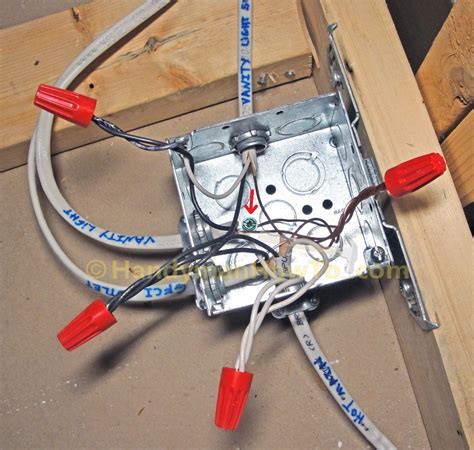

In a system with metal boxes, the pigtail method is considered the most secure. In this arrangement, both the receptacle and metal box are grounded. Ground wires are spliced together and attached with a pigtail to the box and receptacle. The grounding wire nut shown has a hole in its top that makes installing a pigtail . See more

Where plastic boxes are used, a ground wire typically connects to the receptacle only. Here, where wiring runs through this box to another box, a grounding pigtail connects to the device. See more

metal junction box wire

how to ground wire boxes

Many older ceiling fixtures are not grounded. Recent codes, however, call for grounding electrical wires in fixtures. To do so, connect the fixture's ground lead (usually a stranded wire) to the . See moreMost older switches are not grounded; many switches do not even have a ground screw. However, recent codes call for switches to be grounded. Replace an older switch with a newer one that has a ground screw and connect it to a ground wire. See more 1. Attach Box to Stud. If you’re installing an interior box, use screws or nails to attach the box to a stud, positioned so that the face of the box is flush with the drywall. Exterior boxes should be attached with screws; the back of . Installing a ground wire to your electrical service panel can be done easily with a few hand tools. The codes of some localities differ from NEC (National Electric Code) .

There are a few different ways to ground a metal junction box. One is to use screws and clamps to attach the grounding wire to the box. Another way is to use a bonding .The incoming ground wire or grounding conductor in the electrical box connects to the green ground screw on the receptacle and also, by extension or pigtailing, to the junction box if the . Connect the bare or green wire directly to the green screw on the device. If another cable exits the box to feed downstream devices, connect a pigtail to the equipment-grounding conductors in both cables to attach to the . You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means .

A grounded outlet has three prongs: two flat prongs for the hot and neutral wires, plus a round prong for the ground wire. This third prong provides a safe path for excess electrical current to flow back to the ground, .No code requirements exist to attach a ground wire to a non-metallic electrical box. Only metal boxes need to be grounded. However, the grounding wires in a plastic outlet or switch box should not be cut back so short that they are .Use grounding clips to attach copper ground wires to the metal wall of an electrical junction box. Quick Grounding: Grounding clips offer a fast and convenient way to ground copper wires to an electrical junction box wall, .

Ground wires are spliced together and attached with a pigtail to the box and receptacle. The grounding wire nut shown has a hole in its top that makes installing a pigtail easier. Other methods also work well if installed correctly. 1. Attach Box to Stud. If you’re installing an interior box, use screws or nails to attach the box to a stud, positioned so that the face of the box is flush with the drywall. Exterior boxes should be attached with screws; the back of the . Installing a ground wire to your electrical service panel can be done easily with a few hand tools. The codes of some localities differ from NEC (National Electric Code) standards. Be sure to check local codes before performing any wiring job.

There are a few different ways to ground a metal junction box. One is to use screws and clamps to attach the grounding wire to the box. Another way is to use a bonding jumper. A bonding jumper is a piece of metal connected to the grounding screw on the box and then attached to the ground electrical system.The incoming ground wire or grounding conductor in the electrical box connects to the green ground screw on the receptacle and also, by extension or pigtailing, to the junction box if the electrical box is metal not plastic. Connect the bare or green wire directly to the green screw on the device. If another cable exits the box to feed downstream devices, connect a pigtail to the equipment-grounding conductors in both cables to attach to the grounding screw. You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means exists for replacement switches.

how to ground electrical boxes

A grounded outlet has three prongs: two flat prongs for the hot and neutral wires, plus a round prong for the ground wire. This third prong provides a safe path for excess electrical current to flow back to the ground, protecting you from potential shocks and .No code requirements exist to attach a ground wire to a non-metallic electrical box. Only metal boxes need to be grounded. However, the grounding wires in a plastic outlet or switch box should not be cut back so short that they are challenging to work with.Use grounding clips to attach copper ground wires to the metal wall of an electrical junction box. Quick Grounding: Grounding clips offer a fast and convenient way to ground copper wires to an electrical junction box wall, allowing you to run more wire in less time; Easy Installation: To ground conductors, simply thread bare wire through the . Ground wires are spliced together and attached with a pigtail to the box and receptacle. The grounding wire nut shown has a hole in its top that makes installing a pigtail easier. Other methods also work well if installed correctly.

1. Attach Box to Stud. If you’re installing an interior box, use screws or nails to attach the box to a stud, positioned so that the face of the box is flush with the drywall. Exterior boxes should be attached with screws; the back of the . Installing a ground wire to your electrical service panel can be done easily with a few hand tools. The codes of some localities differ from NEC (National Electric Code) standards. Be sure to check local codes before performing any wiring job.

There are a few different ways to ground a metal junction box. One is to use screws and clamps to attach the grounding wire to the box. Another way is to use a bonding jumper. A bonding jumper is a piece of metal connected to the grounding screw on the box and then attached to the ground electrical system.

The incoming ground wire or grounding conductor in the electrical box connects to the green ground screw on the receptacle and also, by extension or pigtailing, to the junction box if the electrical box is metal not plastic. Connect the bare or green wire directly to the green screw on the device. If another cable exits the box to feed downstream devices, connect a pigtail to the equipment-grounding conductors in both cables to attach to the grounding screw. You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means exists for replacement switches. A grounded outlet has three prongs: two flat prongs for the hot and neutral wires, plus a round prong for the ground wire. This third prong provides a safe path for excess electrical current to flow back to the ground, protecting you from potential shocks and .

No code requirements exist to attach a ground wire to a non-metallic electrical box. Only metal boxes need to be grounded. However, the grounding wires in a plastic outlet or switch box should not be cut back so short that they are challenging to work with.

grounding electrical wires in fixtures

grounding electrical wire in box

ground wire to electrical panel

electrical wire grounding guide

Sheet metal parts are made with a constant thickness. They start out as one flat sheet and then are cut and bent to make the final product. When it comes to creating a sheet metal part in SOLIDWORKS you have two choices for the first step: converting to sheet metal or building up from a base.

electrical box grouding wire attachment|how to ground electrical boxes