cnc machine sales blog Typically, a well-maintained CNC machine can serve your manufacturing needs for . Learning how to properly extend electrical wires with a junction box can help you save time and money and ensure that the wiring in your home or business is up to code and secure. Can You Use A Junction Box To Extend .

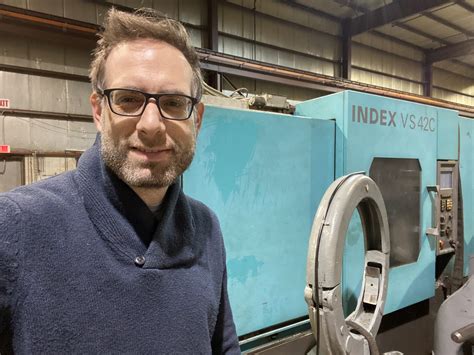

0 · today's machining world blog

1 · today's machining world

As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision .

Explore our CNC Machinery Blog for insider insights, expert interviews, and essential guides on buying and selling CNC machines. Discover practical tips, success stories, .Choosing the best CNC machine involves balancing several factors, including cost, .

Typically, a well-maintained CNC machine can serve your manufacturing needs for . Featuring weekly blogs by industry insider and machinery business expert Lloyd Graff. CNC lathes, vertical machining centers, screw machines, CNC Swiss, multi-spindle . Discover everything you need to know about CNC machine sales, including the advantages, factors to consider, choosing between new and used machines, finding reliable .

Modern Machine Shop is the leading publication and media brand in North America devoted to CNC machining. MMS combines unprecedented editorial access to . Want the Latest CNC Blogs and News? Sign up for Our Used CNC Blog Newsletter. Premier Equipment specializes in used CNC machines with equipment such as . Choosing the best CNC machine involves balancing several factors, including cost, machine capabilities, and after-sales support. Clark Machinery Sales not only offers a . Typically, a well-maintained CNC machine can serve your manufacturing needs for anywhere from 10 to 20 years, depending on usage intensity, maintenance routines, and the .

Sign up to get interesting information on the manufacturing industry, articles about CNC machining, upcoming machines sales, auctions and events, as well as machine . Here are some ways CNC machine shops can increase their sales through branding and digital marketing. There are options for every budget size: See the companies who are searching for your CNC machining services right .

There are several primary methods of selling used CNC machines, each with different qualities, advantages and disadvantages. These methods are: Direct-to-buyer/cash sale: In this method, you, as the seller, manage and . Explore our CNC Machinery Blog for insider insights, expert interviews, and essential guides on buying and selling CNC machines. Discover practical tips, success stories, and the latest industry trends to stay ahead. Featuring weekly blogs by industry insider and machinery business expert Lloyd Graff. CNC lathes, vertical machining centers, screw machines, CNC Swiss, multi-spindle machines, tooling, cutting tools, milling machines, bar loaders, wire EDM and more.

Discover everything you need to know about CNC machine sales, including the advantages, factors to consider, choosing between new and used machines, finding reliable suppliers, and understanding the total cost of ownership. Modern Machine Shop is the leading publication and media brand in North America devoted to CNC machining. MMS combines unprecedented editorial access to manufacturing facilities with decades of experience to provide long-form content that is both insightful and impactful.

Want the Latest CNC Blogs and News? Sign up for Our Used CNC Blog Newsletter. Premier Equipment specializes in used CNC machines with equipment such as used CNC lathes, used CNC mills and used CNC verticals. Choosing the best CNC machine involves balancing several factors, including cost, machine capabilities, and after-sales support. Clark Machinery Sales not only offers a wide selection of brands but also provides the expertise to guide you in selecting the machine that best fits your requirements. Typically, a well-maintained CNC machine can serve your manufacturing needs for anywhere from 10 to 20 years, depending on usage intensity, maintenance routines, and the machine's original build quality.

today's machining world blog

Sign up to get interesting information on the manufacturing industry, articles about CNC machining, upcoming machines sales, auctions and events, as well as machine inspection and maintenance video tutorials. Here are some ways CNC machine shops can increase their sales through branding and digital marketing. There are options for every budget size: See the companies who are searching for your CNC machining services right now with a custom prospect report.

steel truck tool boxes for sale

There are several primary methods of selling used CNC machines, each with different qualities, advantages and disadvantages. These methods are: Direct-to-buyer/cash sale: In this method, you, as the seller, manage and facilitate every aspect of the sale. Explore our CNC Machinery Blog for insider insights, expert interviews, and essential guides on buying and selling CNC machines. Discover practical tips, success stories, and the latest industry trends to stay ahead.

Featuring weekly blogs by industry insider and machinery business expert Lloyd Graff. CNC lathes, vertical machining centers, screw machines, CNC Swiss, multi-spindle machines, tooling, cutting tools, milling machines, bar loaders, wire EDM and more. Discover everything you need to know about CNC machine sales, including the advantages, factors to consider, choosing between new and used machines, finding reliable suppliers, and understanding the total cost of ownership. Modern Machine Shop is the leading publication and media brand in North America devoted to CNC machining. MMS combines unprecedented editorial access to manufacturing facilities with decades of experience to provide long-form content that is both insightful and impactful. Want the Latest CNC Blogs and News? Sign up for Our Used CNC Blog Newsletter. Premier Equipment specializes in used CNC machines with equipment such as used CNC lathes, used CNC mills and used CNC verticals.

Choosing the best CNC machine involves balancing several factors, including cost, machine capabilities, and after-sales support. Clark Machinery Sales not only offers a wide selection of brands but also provides the expertise to guide you in selecting the machine that best fits your requirements. Typically, a well-maintained CNC machine can serve your manufacturing needs for anywhere from 10 to 20 years, depending on usage intensity, maintenance routines, and the machine's original build quality. Sign up to get interesting information on the manufacturing industry, articles about CNC machining, upcoming machines sales, auctions and events, as well as machine inspection and maintenance video tutorials. Here are some ways CNC machine shops can increase their sales through branding and digital marketing. There are options for every budget size: See the companies who are searching for your CNC machining services right now with a custom prospect report.

today's machining world

Work offsets are reference points used to establish the relationship between the machine's coordinate system and the workpiece. By accurately setting work offsets, you tell the CNC machine where the workpiece is located in relation to the coordinate system, enabling precise machining operations.

cnc machine sales blog|today's machining world