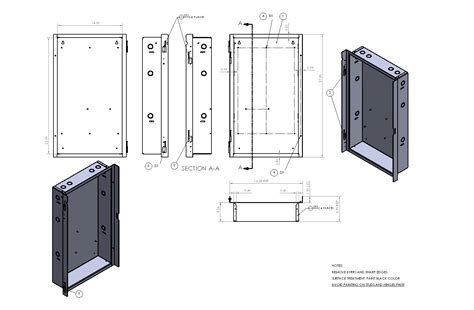

development sheet metal Have you ever struggled with accurately unfolding sheet metal parts? This article explores the art and science behind sheet metal unfolding calculations. Discover the key concepts, formulas, and techniques used by . IP68 External Junction Box, 2 Way Plug Line Outdoor Electrical Box, M20 Coaxial Cable Connector Wire Range 4 to 11mm, Cable Box Enclosure for Trailer, Electric Power Cord .

0 · sheet metal layout drawings

1 · sheet metal development calculator

2 · sheet metal design and fabrication

3 · sheet metal bending chart

4 · sheet metal basic design guidelines

5 · free sheet metal layout patterns

6 · free sheet metal layout books

7 · basics in sheet metal design

$589.95

This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos and animations, the learner has an .A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern. With your compass, take the large slant height from the elevation view and swing an arc from the radius point. .

Have you ever struggled with accurately unfolding sheet metal parts? This article explores the art and science behind sheet metal unfolding calculations. Discover the key concepts, formulas, and techniques used by .

Development: Sheet Metal Level 1. To download the book in a different format, look for the “Download this book” drop-down menu and select the file type you want.

Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = .

Complete, automated sheet metal design with purpose-built tools. To meet unique sheet metal design challenges, such as manufacturability, Solid Edge streamlines the entire sheet metal product development process, from CAD design .Identify the methods for processing sheet-metal patterns. Describe the general principles of pattern development. Discuss the three main types of pattern development. Prepare patterns .

How to calculate the development of a bended metal sheet knowing the position of the neutral fiber? We are going to give two very simple formulas to calculate the neutral fiber in an “L” shape and another one for a “U” shape and we will . This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos and animations, the learner has an opportunity to play, pause, and rewind as they practice these techniques.

A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. Sheet metal layout drawings are based on three types of .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern. With your compass, take the large slant height from the elevation view and swing an arc from the radius point. Set your compass to the small slant height and swing it from the same radius point. Have you ever struggled with accurately unfolding sheet metal parts? This article explores the art and science behind sheet metal unfolding calculations. Discover the key concepts, formulas, and techniques used by experienced engineers to .

Development: Sheet Metal Level 1. To download the book in a different format, look for the “Download this book” drop-down menu and select the file type you want.Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside dimensions of the two legs of the bent part; the object is to determine the correctComplete, automated sheet metal design with purpose-built tools. To meet unique sheet metal design challenges, such as manufacturability, Solid Edge streamlines the entire sheet metal product development process, from CAD design through flat pattern and drawing development.

Identify the methods for processing sheet-metal patterns. Describe the general principles of pattern development. Discuss the three main types of pattern development. Prepare patterns using the three main types of pattern development. Prepare patterns for . How to calculate the development of a bended metal sheet knowing the position of the neutral fiber? We are going to give two very simple formulas to calculate the neutral fiber in an “L” shape and another one for a “U” shape and we will . This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos and animations, the learner has an opportunity to play, pause, and rewind as they practice these techniques.A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. Sheet metal layout drawings are based on three types of .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern. With your compass, take the large slant height from the elevation view and swing an arc from the radius point. Set your compass to the small slant height and swing it from the same radius point. Have you ever struggled with accurately unfolding sheet metal parts? This article explores the art and science behind sheet metal unfolding calculations. Discover the key concepts, formulas, and techniques used by experienced engineers to .Development: Sheet Metal Level 1. To download the book in a different format, look for the “Download this book” drop-down menu and select the file type you want.

Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside dimensions of the two legs of the bent part; the object is to determine the correctComplete, automated sheet metal design with purpose-built tools. To meet unique sheet metal design challenges, such as manufacturability, Solid Edge streamlines the entire sheet metal product development process, from CAD design through flat pattern and drawing development.

metal hole in fabric

12 Pack: Tulip® Metallics™ Dimensional Fabric Paint, 4oz. Only 14 left in stock - order soon.

development sheet metal|sheet metal bending chart