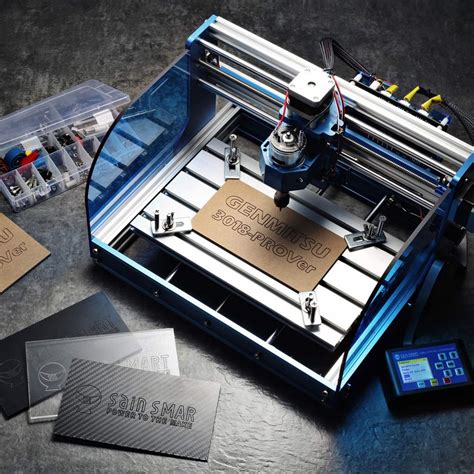

about cnc milling machine CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter . If you can put a patch over so you know you have good metal to weld to. I would stay away from arc welding because it digs into the metal so much and you will end up with a .

0 · types of cnc milling machines

1 · most affordable cnc milling machines

2 · cnc milling machine pdf

3 · cnc milling machine near me

4 · cnc milling machine description

5 · cnc milling machine definition

6 · best milling machine for small shop

7 · affordable cnc milling machines

The Lippert L05 extended pin box is a direct replacement for your Lippert 1621HD pin box on your 5th wheel trailer. It has a gross vehicle weight (GVW) rating of 18,000 lbs. with a king pin that connects to any 5th wheel trailer hitch, so it is ready to .

Milling machines can machine materials such as metal, plastic, or wood. Mills use cutting tools including end mills, face mills, and drills. They can feature high-quality cast iron construction, variable speed capability, power . CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter . A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages .In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials.. Unlike manual milling, .

CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products. Milling machines can machine materials such as metal, plastic, or wood. Mills use cutting tools including end mills, face mills, and drills. They can feature high-quality cast iron construction, variable speed capability, power feeds, and . CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter toolpath, feed . A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision.

In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials.. Unlike manual milling, where an operator’s steady hand (or lack thereof) makes all the difference, CNC milling brings a super-high level of consistency that manual methods could only dream of. A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for completing the milling process.

types of cnc milling machines

CNC milling is a subset of CNC machining services, a broadly defined manufacturing process that includes CNC turning, CNC routing, and CNC drilling. CNC machining describes technologies that utilise computer-controlled tools to carve out portions of a block of material to create a part. What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. The process begins with a 3D CAD model converted into a . Dive into the introduction to CNC milling with this beginner's guide. Explore the basics, CNC milling processes, and insights to kickstart your CNC journey.

CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products. Milling machines can machine materials such as metal, plastic, or wood. Mills use cutting tools including end mills, face mills, and drills. They can feature high-quality cast iron construction, variable speed capability, power feeds, and .

CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter toolpath, feed . A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision.In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials.. Unlike manual milling, where an operator’s steady hand (or lack thereof) makes all the difference, CNC milling brings a super-high level of consistency that manual methods could only dream of.

A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for completing the milling process.CNC milling is a subset of CNC machining services, a broadly defined manufacturing process that includes CNC turning, CNC routing, and CNC drilling. CNC machining describes technologies that utilise computer-controlled tools to carve out portions of a block of material to create a part. What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. The process begins with a 3D CAD model converted into a .

most affordable cnc milling machines

cnc milling machine pdf

cnc milling machine near me

Cabinets can hold up to 600 lbs, but it depends on factors. Solid wood cabinets have the highest weight capacity. Hardware and design affect weight capacity. Wall cabinets have lower load-bearing capabilities than base cabinets. .

about cnc milling machine|cnc milling machine pdf